Weld lines result

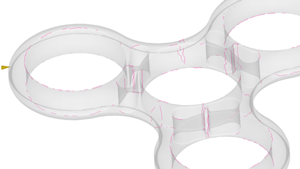

The Weld lines result shows the angle of convergence as two flow fronts meet. The presence of weld lines may indicate a structural weakness and/or a surface blemish.

Weld lines

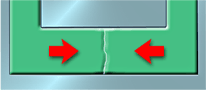

A weld line is a weakness or visible flaw created when two or more flow paths meet during the filling process. They can be caused by holes or inserts in the part, multiple injection locations, or variable wall thickness where flow slows down (hesitation) or gathers speed (race tracking). If the different flow fronts cool before meeting, they may not recombine well, causing a weakness in the molded part. A line, notch/ and/or color change may also occur.

The visual appearance of the weld line, and the strength of the model at that location, depend on the material type, the presence and volume of fillers, and the pressure and temperature at the weld line.

Things to look for

In the Weld lines result, weld lines appear as thin, colored lines on a transparent model. The Weld Lines result helps you to identify the following problems:

- Structural problems: The part may be more likely to fracture or deform at a weld line, especially if the weld line is of a low quality. This weakness is a more serious problem in areas of the part that are subject to stress.

- Visual defects: A weld line can cause a line, notch, or color change on the surface of the part. If the weld line is positioned on a non-critical part surface, such as the bottom, this may not be a problem.

Using this result

Consider the processing conditions and position of the weld lines to determine whether the weld lines will be high quality. Weld and meld lines should be avoided, particularly weld lines in areas that require strength or a smooth appearance. Move weld lines to areas where strength is of less importance and their visual appearance is less obvious. Weld lines can be moved by changing the fill pattern to make the flow fronts meet at a different place.

Next steps

To move weld lines:

- Alter the position of the injection locations

- Change the thickness of the model.

To improve the quality of the weld lines:

Increase the melt temperature, or injection speed. This enables the flow fronts to weld to each other more effectively.

Move injection locations to make flow fronts meet more obliquely, turning the weld line into a meld line.