A sheet metal Lofted Flange feature allows shape definition using two profile sketches. The sketch geometry can represent the inside or outside face of the sheet metal material. It can also represent the material midplane. Often a closed profile most easily defines both ends of a transitional shape. These types of designs are readily recognized in commonly encountered situations including: duct work, ventilation exhaust hoods, and any number of container shapes.

Lofted Flange features created with closed profile sketches at either end can easily be flattened following the addition of a sheet metal Rip feature.

Autodesk Inventor supports the output of Lofted Flange features to either a smooth, die-formed model, or to a model capable of being produced using the straight bends of a press brake.

Lofted flange examples

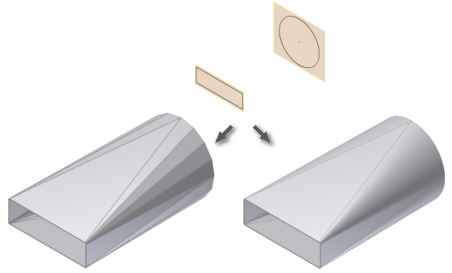

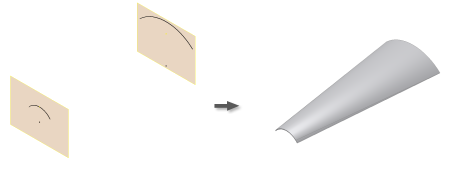

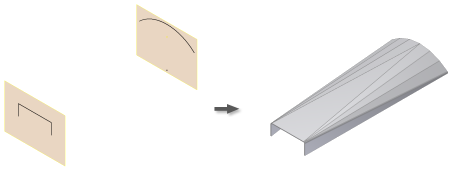

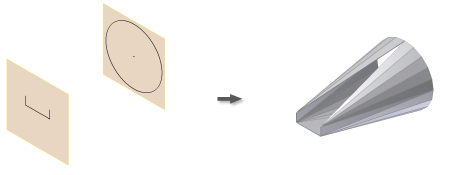

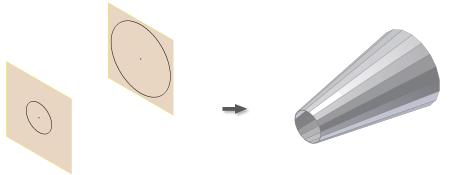

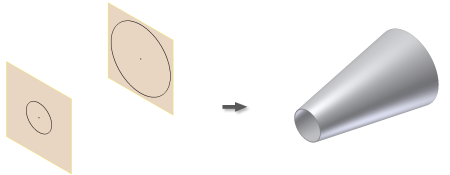

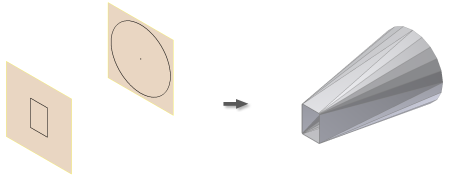

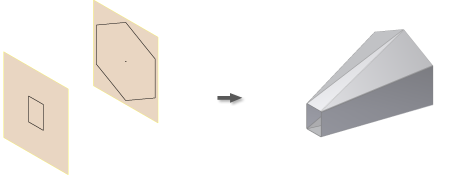

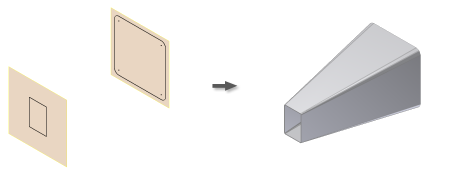

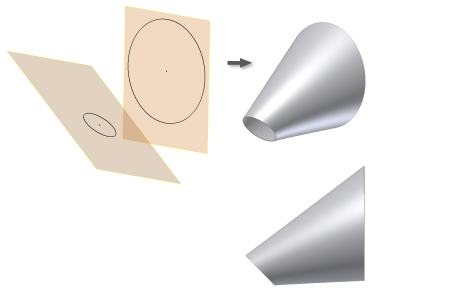

The following illustrations show examples of various input and output options for Lofted Flange features.

Similar Open Profiles - Die Formed Output

Dissimilar Open Profiles - Press Brake Output

Closed to Open Profiles - Press Brake Output

Circular Closed Profiles - Press Brake Output

Circular Closed Profiles - Die Formed Output

Circular to Sharp-corner Rectangle Closed Profiles - Press Brake Output

Polygon to Sharp-corner Rectangle Closed Profiles - Die Formed Output

Radius-corner to Sharp-corner Rectangle Closed Profiles - Press Brake Output

Non-Parallel Circular Closed Profiles - Die Formed Output