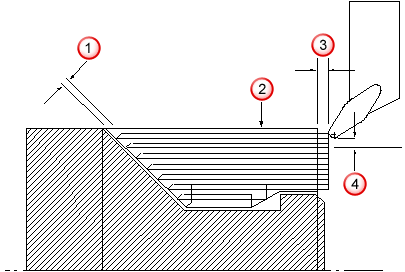

You can use the Boring tab of the Turning Feature Properties dialog to edit the machining settings of a Boring feature.

Constant DOC — See Depth of cut

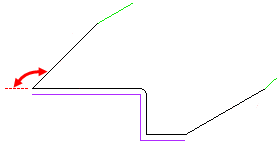

Rough engage angle — Enter the angle at which the tool enters the stock for boundary moves. This attribute is available for the rough pass when TNR comp is off. For the Semi-finish and Finish pass, this attribute is available on the Leads tab.

Lead-in angle — Enter the angle at which the tool enters the stock for boundary moves. This attribute is available for the rough pass if TNR comp is on. For the Semi-finish and Finish pass, this attribute is available on the Leads tab.

Lead-out angle — Enter the angle for the lead-out move, measured clockwise away from the part. An angle of

0 exits along the direction of path. An angle of

90

exits along the direction of path. An angle of

90 exits perpendicular to the path. This attribute is available when

TNR comp is on. For the Semi-finish and Finish pass, this attribute is available on the

Leads tab.

exits perpendicular to the path. This attribute is available when

TNR comp is on. For the Semi-finish and Finish pass, this attribute is available on the

Leads tab.

Tool change location is the point where the tip of the tool moves before a tool change.

Undercuts — Select from No checking, Adjust to tool geometry, and Remove all undercuts.

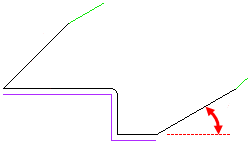

Withdraw angle — Enter the angle for the lead-out move, measured clockwise away from the part. This attribute is available when TNR comp is off. For the Semi-finish and Finish pass, this attribute is available on the Leads tab.

Withdraw length — This is the distance along the withdraw angle line in which the tool withdraws before returning for the next step.

Withdraw length

Withdraw length

Boundary

Boundary

Clearance

Clearance

Depth

Depth