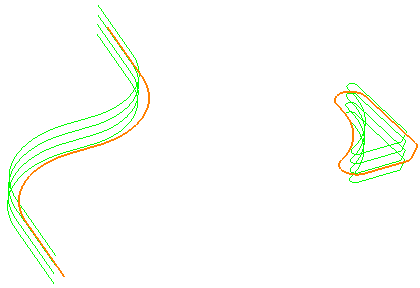

Use the 2D Curve Profiling strategy to create a simple 2D machining toolpath following one or more curves at a single Z height.

To create a 2D curve toolpath:

- Construct the curves you want to machine.

- Assign machining properties to the curves.

- Generate the toolpath.

There are several pages associated with the Curve Profile strategy:

- Curve profile — The main page used to define a curve profile toolpath.

- Cut distances — Settings to specify multiple passes.

- Finishing — Settings to specify a final stepover or stepdown depth of cut value.

- Draft — Settings to define toolpaths with draft angles.

- Rest — Settings to define rest machining.

- Offset — Settings to create a spiral toolpath to minimise lifts.

- Step cutting — Settings to define in-line rest roughing. This minimises terracing when creating area clearance toolpaths with a large stepdown. This is available when you select a Stepdown of Automatic.

- High speed — Settings for the smoothing options to avoid sharp changes in tool direction when high speed machining.

- Order — Settings to control the order of machining.

- Approach — Settings to control how the tool approaches the path.

- Automatic verification — Settings to automatically verify toolpaths on creation.

The remaining pages are common toolpath strategy pages.