Setup reference

Common setup parameters for the type of machining operation, model orientation and origin, fixture selection, stock specifications, and post processing are configured on the Setup operation dialog.

Manufacture > Setup > New Setup ![]()

A setup defines what you want to machine and how. It is the first thing you create in the Manufacture workspace and is used to contain manufacturing operations.

In general, for subtractive manufacturing, when you create a setup, you specify the:

- Machine and operation type you want to use

- Model that represents the part to be machined

- Work coordinate system's orientation and origin location

- Stock to define the size and dimensions of the workpiece

- Post-processor selection

Setup tab settings

Setup tab settings

Machine

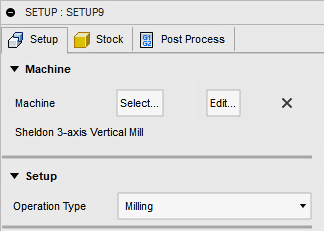

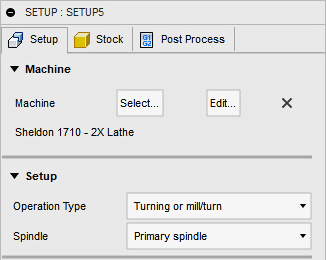

Select opens the Machine Library, where you can select a machine. Selecting a machine automatically selects the Operation Type.

|

|

| Milling Machine selected. Operation Type is Milling |

Turning Machine selected. Operation Type is Turning or Mill/Turn |

Operation Type

The Operation type, determines which toolpaths will be available. If you do not select a Machine from the Machine Library, you can select the Operation type manually.

|

|

|

|

| Milling 2-5 axis mills |

Turning or Mill/Turn 2-5 axis lathes |

Cutting Plasma, Waterjet or Laser |

Additive 3D Printing |

Operation Type - Turning or Mill/Turn

Turning or Mill/Turn Is for standard 2 axis lathes, lathes with live tooling and mill/turn configurations. This includes settings for multi-spindle lathes.

Spindle

For machines with multiple spindles. Specifies which spindle is being programmed in this Setup.

- Main spindle

- Subspindle

Work Coordinate Setting (WCS)

WCS allows you to set the working XY plane and the Z spindle axis orientation. The machining process determines the orientation of the part, the axes direction and part zero position. Select the process below for additional information.

|

|

|

|

| Milling 2-5 axis mills |

Turning or Mill/Turn 2-5 axis lathes |

Cutting Plasma, Waterjet or Laser |

Additive 3D Printing |

For more information, watch the Set up a collaborative project for a distributed design video.