Live part alignment using probing

This feature is part of an extension. Extensions are a flexible way to access additional capabilities in Fusion. Learn more.

The Live Part Alignment ![]() feature helps automate the setting up of complex, free-form parts on a CNC machine. Examples include castings, forgings, and near net shapes.

feature helps automate the setting up of complex, free-form parts on a CNC machine. Examples include castings, forgings, and near net shapes.

Using surface inspection results, Fusion calculates a part alignment to compensate for any misalignment or imprecise fixturing of the part on the CNC machine. It then adjusts the work coordinate system (WCS) on the machine controller so that the parts can be machined accurately.

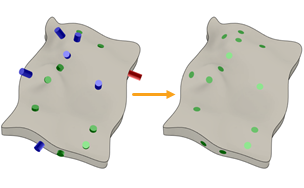

Example of inspection results before (left) and then after (right) a part alignment has been applied.

Creating a part alignment helps:

- Save time by avoiding manual part setting using dial indicators.

- Remove the need for complex fixturing of parts.

- Reduce the scrapping of parts after machining because of inaccurate setup.

- Increase repeatability, part accuracy, and process reliability.

Automation

Surface inspection results are imported in real-time using a live connection between Fusion and the CNC machine. Compared to using the Part Alignment feature, the Live Part Alignment feature provides a quicker, more automated workflow by removing the need for a machine operator to import a machine-generated results file. It also removes the need to post process a second time.

In addition, you can instruct Fusion to automatically approve or reject a calculated part alignment based on inspection results. For example, if all the inspection results are in tolerance after a part alignment has been applied, the CNC machine can continue to run the rest of the NC code using the calculated part alignment.