Tutorial: Modal frequencies analysis

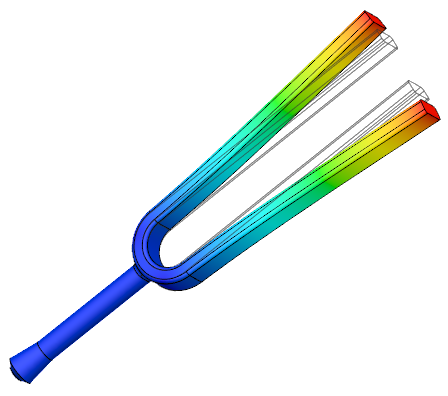

This tutorial uses Modal Frequencies analyses to let you practice interpreting results and modifying geometry. You determine the frequency (musical pitch) of the first fundamental vibration mode of a tuning fork. You then adjust the length of the prongs, on the production model, and reanalyze the model to approximately achieve the desired target pitch.

In this tutorial, you

Create a Modal Frequencies study to determine the frequency of the first fundamental vibration mode of a tuning fork,

Run the analysis, identify the first fundamental vibration mode, and determine whether the prongs needed to be lengthened or shortened,

Lengthen the prongs on the production model to lower the vibrating frequency, rerun the analysis and confirm that the natural frequency is 418 Hz,

Determine the exact prong length required to produce the A4 musical pitch of 440 Hz, and calculate how much material needs to be ground off the ends of the rough tuning fork prongs to tune the pitch to 440 Hz.

Modal Frequency result on a tuning fork.

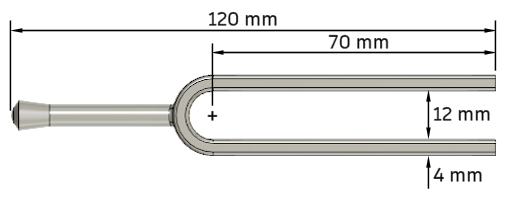

Design parameters

Tuning Fork Designation: A4 (440 Hz)

Target Frequency: Approximately 95% of the desired musical pitch. 0.95 * 440 Hz = 418 Hz

Note: The vibrating frequency increases as the prongs are shortened. The final pitch is precisely achieved by grinding material off of the ends of the prongs. Therefore, the prongs initially need to be slightly longer than the required length. This 5% grinding stock accounts for variations in manufacturing tolerances and material density and stiffness. It ensures that the rough cut fork vibrates at less than the standard A4 musical pitch. Therefore, material must be removed from the fork, and never has to be added to it, to achieve the final pitch.Material: Stainless Steel AISI 304

No constraints applied: Because a tuning fork is held loosely in a person's hand, the model is unconstrained. Any fixed constraints would affect the resulting natural frequencies and mode shapes. Because the model is unconstrained, six rigid-body vibration modes are expected. We expect the seventh mode to be the one of interest.

Mesh Size: Specify an absolute mesh size of 1.2 mm.

Number of Modes to calculate: 12

Initial geometry