You need to consider ply (or ply subdivision) thicknesses from TruPlan if you want an accurate representation of your model, and especially if you plan on doing laser projections. This is because thicknesses are used to calculate the offset value for laser projection output. This offset value is also used to generate new surfaces accounting for the layers that are created, as well as the boundaries transferred to this surface. However, calculating thickness offsets can create a lot of data and slow down processing speed.

For this reason, TruPlan enables you calculate thickness offsets in a variety of ways.

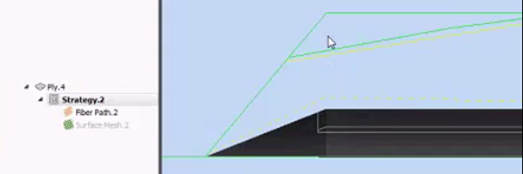

- You can create actual surfaces on plies, stored with the project and visible in the application window. (Right-click a ply or ply subdivision and select Include Surface Offset.) This provides good performance but can greatly increase file size. This can be done during or after import of composites files.

- You can create calculated offsets in strategies; these are used to generate accurate fiber paths and meshes for plies, but they are not shown as surfaces in the application window and are not stored in the project as surfaces. This reduces file size but can impact performance.

- You can also use a combination of the previous two options: Create a surface every few plies within your project, then enable strategies to calculate offsets based on these surfaces.

When thickness offsets are enabled, the results might not be visible in TruPlan if your tessellation settings are too low. If this happens, right-click your surface in the TruPlan browser, select Properties, and import an STL file with a finer tessellation.

Calculate Ply Thicknesses During Import

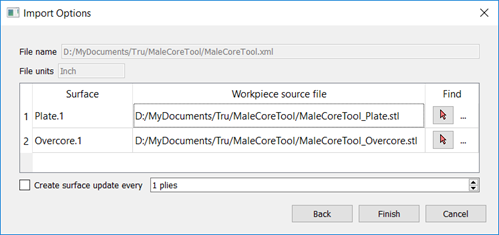

When you import XML files, you can create offsets that are stored with the project. You can also elect to bypass thickness calculation so that you can work quickly in TruPlan; for example to do feasibility studies on the general shape of a part. If you bypass offset calculation on import, you can still enable it later in other places in TruPlan.

- Click

Open Composites or

Insert Composites on the

TruPlan ribbon.

(The name of the button depends on whether you already have a file open.)

- Browse to the XML file you want and click

Open.

The Import Options dialog box opens. (This dialog box's appearance varies, depending on the contents of the file being imported.)

- Select

Create Surface Update Every and select the interval at which surfaces should be created.

By default, this is always deselected when importing files, because it can impact performance.

Enable Thickness Calculation in Strategies

If you did not enable thickness calculation during import, you can do so in the strategy dialog box for a ply.

- In the

TruPlan browser, double-click a strategy, or select a ply and click

Strategy on the

TruPlan ribbon to create a ply.

The Strategy dialog box opens.

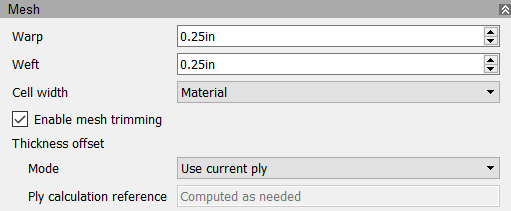

- In the Mesh section of the Strategy dialog box, select a mode under

Thickness Offset.

- Use Current Ply: Calculate the ply's offset value within the strategy itself. This provides the most accurate representation of thickness but can use a lot of processing power. (For a sub-ply, thickness is determined by the parent subdivision.)

- Use Existing: Use the most recently stored ply offset that precedes the strategy. This can provide a reasonably accurate representation of thickness without requiring a lot of processing power.

- Disabled: Do not calculate the offset value.

Include Surface Offset for a Ply

Ply thickness might already be calculated for a ply if:

- The ply was imported and you enabled thickness calculation during import, or;

- At least one strategy for the ply has thickness offset enabled.

However, another alternative is to enable this from the Ply context menu.

- Right-click the ply in the TruPlan browser.

- Select Include Surface Offset.

This enables you to include thickness offset in laser projection output even if no strategy is defined for the ply, or if you bypassed thickness calculation during import.

For sub-plies, thickness offset is inherited from the parent ply down through the subdivision and sub-plies. If a ply has thickness offset enabled, then you can select an offset type on each of its subdivisions, which are then applied to their sub-plies. To set the offset type for a subdivision, double-click it in the TruPlan browser and select a type from the Thickness Offset box.

Show or Hide Stored Offsets

To help improve performance, stored offset surfaces are hidden by default when you create them. They are represented by nodes in the TruPlan browser. Right-click these and select Visibility to see them at any time.

Calculate Thickness of Cured or Uncured Plies

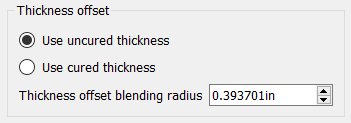

When calculating ply thicknesses for use with laser projection, you need to consider whether the plies will be cured or uncured. The default behavior in TruPlan is for thickness to be calculated based on uncured plies. However, a ply’s thickness can change when it is cured. Plies are commonly cured only after they are all applied, but in some cases, they need to be cured during the manufacturing process. For example, you might cure one layup of plies before applying the next layup. You take this into account using thickness offset options in the Layup dialog box.

- In the TruPlan browser, double-click a layup, or click Layup on the TruPlan ribbon to create a layup.

- In the Layup dialog box, under Thickness Offset, select whether to calculate offsets as cured or uncured for the plies within the layup.

This only has an effect if you enabled any offsets in the layup. It uses the cured or uncured values found in the Properties tab of the Composites Library.

- If you selected Use Cured Thickness, you also need to set

Thickness Offset Blending Radius.

This value controls the transition between the bounded area of the surface where ply thickness is calculated, and the areas where it is not. A larger radius results in a gradual and smooth transition, while a small radius can result in a shorter and rougher transition. Autodesk recommends a value approximately twice the size of the triangles used for tessellation.