Compression

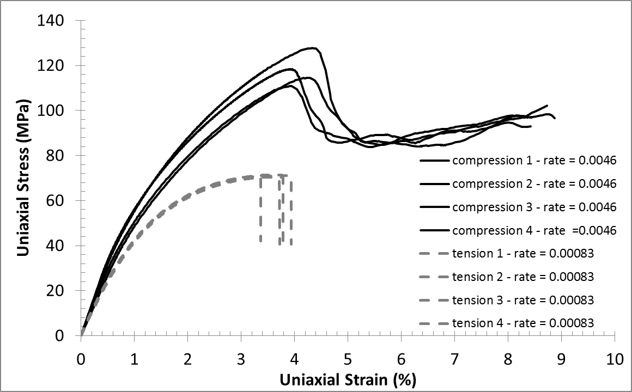

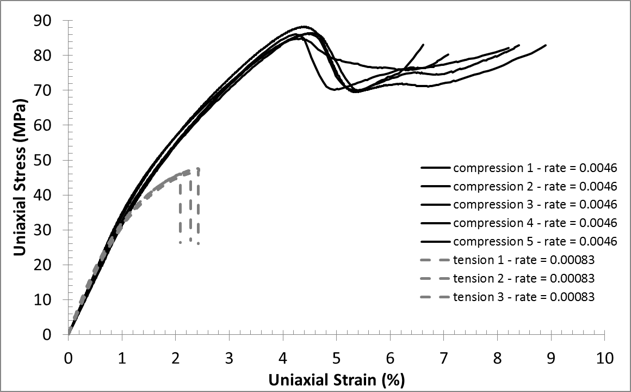

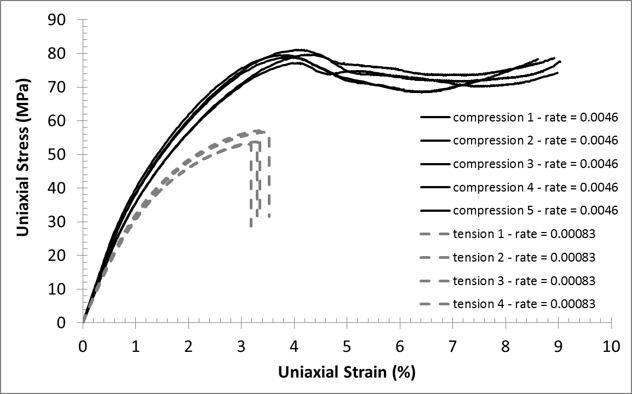

To this point, we have only considered the tensile plasticity and rupture models. Let's turn our focus now to the compressive response. First, consider the three plots below showing common tensile and compressive responses for the three common loading directions.

0°:

90°:

45°:

We notice that the tensile loading causes a higher rate of plastic evolution than the compressive loading (the same is true when the tensile response is captured at a higher strain rate). This means that for a prescribed strain increment, the material exhibits a greater reduction in the tangent modulus if the stress state is tension dominated as opposed to compression dominated.

In terms of rupture, the tensile loading results in failure at relatively low strain levels (2-4%). The compressive loading does not produce rupture, even out to 10% strain. However, these three responses show that compressive loading does result in a significant load drop around 4% strain. The magnitude of the load drop varies depending on the angle of loading relative to the fiber direction. After the load drop is completed, the material resumes the plasticity response.

The topics contained in this section will describe the approach used to capture the compressive response of short fiber-filled materials and discuss how it varies from the tensile model.