Compression

Once a material is characterized for use in a compressive environment, it can be useful to adjust the nonlinear behavior and the rupture of the material. For example, you could turn off failure altogether or instruct Advanced Material Exchange to use the tensile plasticity and rupture models for compression. The nonlinear and rupture flags are controlled with the *COMPRESSION keyword.

*COMPRESSION, FAILURE=[ON/OFF], NONLINEAR=[ON/OFF]where FAILURE=ON and NONLINEAR=ON are defaults. When FAILURE=ON, the compressive rupture criterion is used. When FAILURE=OFF, rupture is not predicted for the compressive environment. The plasticity model will continue to operate as the load increases. When NONLINEAR=ON, the compressive plasticity model is used. When NONLINEAR=OFF, Advanced Material Exchange uses the tensile plasticity and rupture models. The *COMPRESSION must be preceded by a valid *MATERIAL keyword.

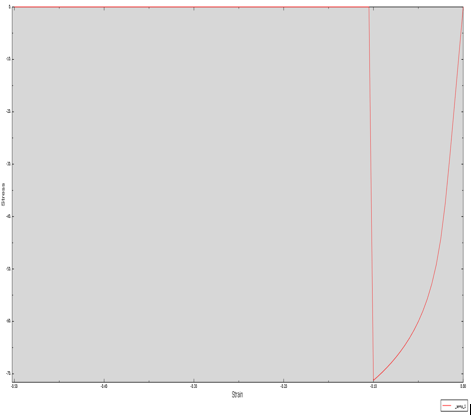

To understand the impact the *COMPRESSION keyword can have, let's take a look at the following examples. In the first example, the default compressive behavior is used.

*MATERIAL, NAME=CA-PLASTIC-1

*COMPRESSION, FAILURE=ON, NONLINEAR=ONIf we create a stress-strain plot for a model under a compressive load, we see a very typical response. Plasticity continues to accumulate as more and more load is applied. At some point, the structure fails and we see a stress drop. After the large stress drop, the model is able to reload due to the physical interference of the failed material.

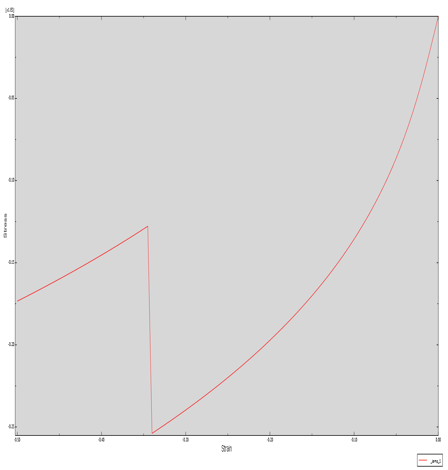

In the second example, the nonlinearity is turned off. As a result, the tensile plasticity and rupture models are used.

*MATERIAL, NAME=CA-PLASTIC-1

*COMPRESSION, FAILURE=ON, NONLINEAR=OFFThe stress-strain curve now exhibits a response typical of a tensile failure. Plasticity continues to accumulate once again, but when the ultimate failure of the structure occurs, the composite stiffness is reduced to a very small number (1E-06 by default). This is evident in the large stress drop.