Material Mapping

The material mapping functionality allows you to map the properties of one material to a new material definition. This lets you control the behavior of the material for a specific region of the model. Mapping materials can allow you to turn failure on or off, modify the material properties, and modify the rupture criterion for a given region of your model to name a few examples.

Use the syntax below to activate the material mapping functionality in the HIN file:

*MAP, FROM=[ID], TO=[ID]

FROM, TOwhere ID is used for Ansys analyses. FROM represents the name of the material in the input file (and HIN file) that contains the modified material properties. TO represents the name of the material in the input file that contains the original material properties. You can think of this as taking the new material (from) and mapping it to the original material definition saved in the .sif file (to).

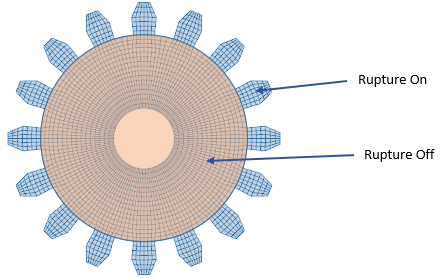

Let's look at an example use case. In this example we want to turn off rupture for the regions of the gear model where we don't expect failure. Let's assume that experimental test results have shown us that failure only occurs in the teeth of the gear, not in the base. Since we are only expecting failure to occur in the teeth, we can turn off rupture for the rest of the model. This has the potential to reduce the runtime for this analysis.

Even though the same plastic material is used throughout the gear, we must setup the structural input file as though two materials are used -- one for the teeth, one for the base.

Set-up Input File for Ansys analyses

Each material must have a TB, USER definition in order to be used with the Helius PFA solver.

MAT,10751

TB,STATE,10751,,20

TB,USER,10751,,0

MAT,20000

TB,STATE,20000,,20

TB,USER,20000,,0Set-up HIN File for Ansys analyses

Now that two materials have been defined in the input file and those materials have been assigned to the appropriate region in the model, we are ready to define the material mapping.

*MAP, FROM=ID, TO=ID

20000, 10751At this point, Advanced Material Exchange knows to use the base properties of our original material for the new material. All that is left to do is use the HIN file to turn off rupture for the new material.

*MATERIAL, ORIGINAL ID=20000

*DAMAGEINITIATION, TYPE=MCT

0,0,0