A variable is used to combine values (from a range, table, logic operator, variable or constant value) to derive another value.

The following example shows a scenario for controlling a boosted flow into an area subject to low pressures within a gravity fed demand area. If the pressure at a sensor in the demand area falls below a given pressure, the booster pump will be switched ON to boost flow to the low pressure area . Under normal conditions, the booster pump will be switched OFF and the entire area will be gravity fed.

In this scenario, a variable is used to calculate a pressure offset at sensor Node A. The default status of the pump is OFF. If the pressure at Node A falls below 20m, the pump will be switched ON.

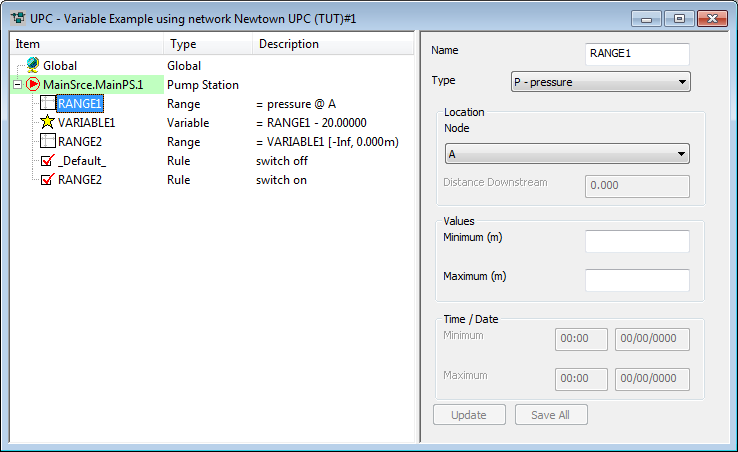

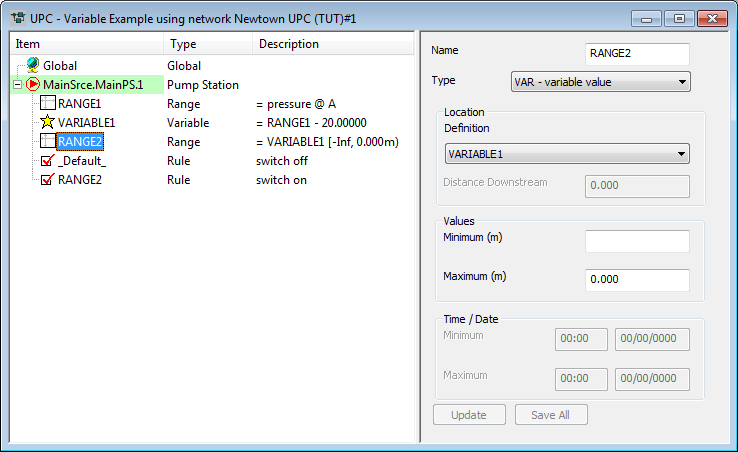

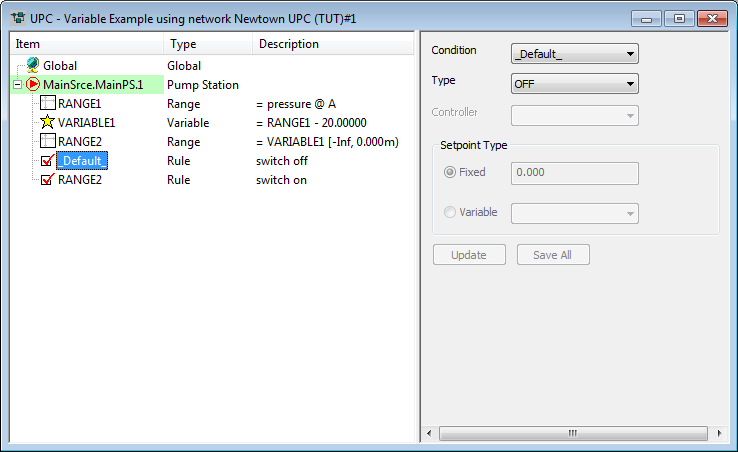

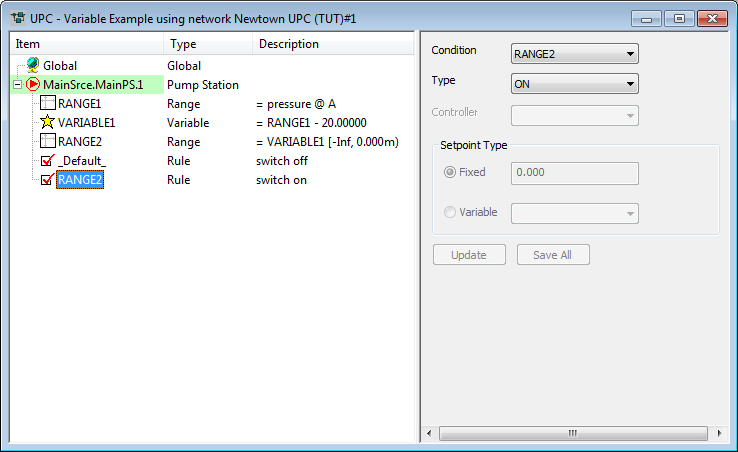

The scenario is defined by adding components to a pump regulator in the UPC window.

| Component | Parameters | Effect |

|---|---|---|

|

RANGE 1 |

Range type: Pressure Location node: A Minimum: Maximum: |

TRUE if pressure at Node A is between -/+ infinity |

|

VARIABLE 1 |

Measurement: Pressure Operator: Minus Argument 1: RANGE 1 Argument 2: Constant (20) |

Pressure at Node A - 20m |

|

RANGE 2 |

Range Type: Variable Location Definition: VARIABLE 1 Minimum: Maximum: 0 |

TRUE if VARIABLE 1 is less than zero. |

|

RULE 1 |

Condition: _default_ Type: OFF |

Default status of pump is OFF |

|

RULE 2 |

Condition: RANGE 2 Type: ON |

Switch pump ON if RANGE 2 is TRUE |

- Range 1: Defines Node A as the control point.

- Variable 1: Calculates offset pressure at Node A.

- Range 2: Defines the calculated offset pressure in Variable 1 as the control with a maximum value of 0.

- Rule 1: Unless subsequent rules are TRUE, switch pump OFF.

- Rule 2: If the pressure offset at Node A is less than 0 (pressure at Node A less than 20m) switch pump ON.

This simple example could be modelled without the use of a variable, by using the actual pressure at Node A instead of an offset. For an example of how the use of variables can be extended, see UPC example (three point PRV).