Quickstart Cool tutorial: Review part temperature results

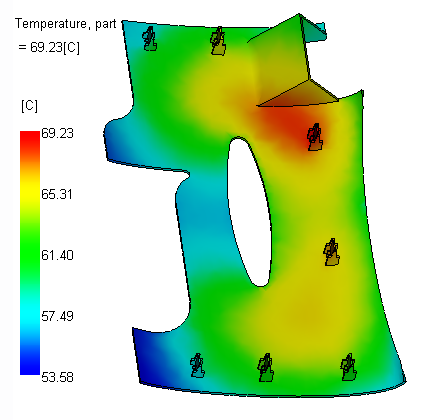

In this task, you interpret the temperature, part results. These results represent the average temperature of the part surface temperature throughout the mold cycle.

Click the Temperature, part results.

In this case, the target temperature is 50 C. The variation in temperature max to min is under 20C which is good. However even the coolest temperature on the part is higher than the target indicating the coolant temperature, in this case 25C is too high.

This result represents the cycle averaged part temperature at the mold surface or plastic/metal interface. The variation in temperature for an amorphous material like the ABS used here, is best when it is ± 10 C from the recommended mold surface temperature. The temperature variation is within a temperature range of 20C but the desirable mold surface temperature needs to be determined.

Right-click on the material in the Study Tasks pane and select Details from the list.

Select Recommended Processing from the Thermoplastic material dialog.

A mold surface temperature of 50C is recommended

The coldest temperature on the part is higher than the target temperature indicating that the coolant temperature of 25C is to high.