Quickstart Fill tutorial: Review results

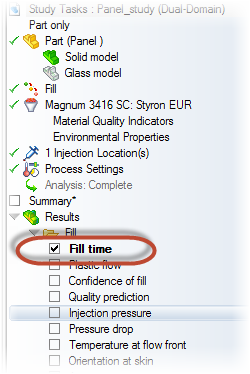

In this task, you review the Fill time results.

Click Fill time in the Study Tasks list.

Rotate, Pan, and Zoom the model as necessary to inspect the fill time result.

Click

(Results tab > Animation panel > Play) to animate the result.

(Results tab > Animation panel > Play) to animate the result.Use the other animation tools to see what they do.

The filling pattern is unidirectional. Because the extremities of the part fill at close to the same time, the fill pattern is considered to be balanced. This gate location produces an acceptable filling pattern.

When analyzing a part without a runner system, the pressure to fill the part is best when under 50% of the machine capacity. If you do not know what specific machine is going to be used, assuming the machine's pressure capacity is 140 MPa is a conservative approach.

Click Injection Pressure in the Study Tasks list.

The injection pressure is over 70 MPa.

As the injection pressure is over 50% your options include:

- Investigate if an alternate injection location requires less pressure

- Increase melt/mold temperature

- Consider multiple injection locations

In the next tutorial you will investigate moving the injection location.