Work with Operations

-

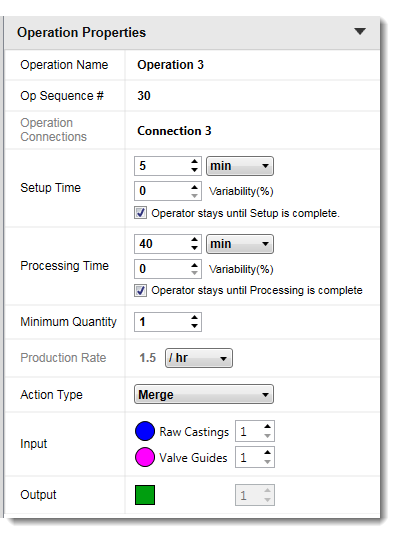

Select a Processor from your process model to adjust Operation settings in the Properties window.

Optionally, to access Operation quick settings on the Processor node, select the + or - to the right of an operation.

-

To change the name or sequence number of an operation, double-click the operation name in the item to be changed on the processor, or change the item from the Operation Properties.

-

To edit the Setup Time or Processing Time, click the Up or Down Arrows, or enter a number in the field. You can select the desired unit of time from the drop-down menu.

-

Select the Operator stays until Processing or Setup is complete options to ensure that the Operator object remains present for the duration of the setup or processing time on that processor or machine.

An Operator can work more efficiently, and move between a series of operations more freely by clearing the Operator stays until Setup or Processing is complete options. Operators can start new work while other operations are still in process. If this option is selected, Operators need to complete one operation before moving on to another operation.

-

To add an operation, select the + symbol to the right of a processor, or right-click on the processor to add an operation. You need to schedule multiple operations individually in the Operation Properties window.

-

To remove an operation, right-click on the operation and select Delete Operation from the context menu.

-

Set the Action Type to Merge, Split, or None in the Operation Properties, or by hovering over the Port of an Operation. By default, the Operation action type is set to None, meaning that the processor has only one input and one output. Select Merge if there are multiple inputs but only one output. Select Split if a single input produces multiple outputs.

Changing the Action Type setting can help you manage production capacity, scheduling, and other manufacturing activities if you have multiple inputs or outputs. For example, if equipment capacity is limited, you can split processing across multiple machines to increase volume, create a partial lot that meets specific customer demands, or manufacture different grades of material. Merges can, for example, bring previously split lots back together to reach target quantities for next-step processing or bring different pieces from multiple lines together for assembly.

-

Change operation output icon colors and shapes from the Operation Properties window. Select More Color to modify RGB colors. Colors and shapes can also be changed by hovering over an operation port and then hovering over the shape icon. Click More Colors to access the RGB color selector.