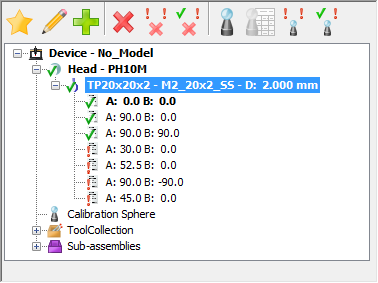

When you connect the document to a CNC machine, PowerInspect checks that the probe head and the probes you specified in the inspection sequence are available on the measuring device. It also checks that all the specified probe positions are calibrated. The details are displayed in the Machine tab:

You must calibrate any uncalibrated positions (indicated by

) before running the inspection on the measuring device. If

PowerInspect is connected to the measuring device using:

) before running the inspection on the measuring device. If

PowerInspect is connected to the measuring device using:

- a device protocol or the I++ ClientTool protocol, click the

Calibrate Uncalibrated

button to calibrate all the uncalibrated positions on the measuring device.

button to calibrate all the uncalibrated positions on the measuring device.

- the I++ protocol, open the I++ Server and calibrate all the items specified in the document.

If you have used different names for the probe assemblies in the I++ Server, click the Synchronise

button in the toolbar and use the

I++ Probe Matching dialog to match the unavailable items to items in the I++ Server.

button in the toolbar and use the

I++ Probe Matching dialog to match the unavailable items to items in the I++ Server.