Use the NC Program verification dialog to check your NC programs for collisions or gouges.

Click Home tab > Verification > NC Program to display the NC program verification dialog.

The dialog contains the following:

— Select an NC program to verify.

— Select an NC program to verify.

— Click to display the

NC programdialog. Use this to view and edit the detail of the NC program.

— Click to display the

NC programdialog. Use this to view and edit the detail of the NC program.

— Displays the name of the machine tool.

— Displays the name of the machine tool.

— Displays the name of the workplane.

— Displays the name of the workplane.

Verify the machine tool

This area contains options which enable you to collision-check the machine tool against itself and other components:

Verify toolpaths — Select to check the toolpaths for collisions involving the machine tool.

Verify connection moves — Select to check the connections for collisions involving the machine tool.

Machine tool clearance — Enter the machine tool clearance you want to use for verification. Entering a value clears the verification for the NC program.

Verify the tool against the model

This area contains options which enable you to collision-check the shank and holder against the model. This does not affect checks with the machine tool.

Verify toolpaths — Select to check for collisions between the tool, the holder and the model.

- Increase toolpath clearances — Select to check for collisions in all toolpaths.

- Keep existing toolpath clearances — Select to check for collisions in all toolpaths that are not verified.

Verify connection moves — Select to include connection moves in the verification.

Holder Clearance — Enter the minimum allowable distance between the model and the tool holder profile.

Shank Clearance — Enter the minimum allowable distance between the model and the tool shank profile.

Safety status indicator — Displays an icon which identifies the most severe issue found in verification.

— Collisions found

— Collisions found

— Other issues, for example, unverified toolpaths.

— Other issues, for example, unverified toolpaths.

— Gouge checked

— Gouge checked

— Gouge, and holder checked

— Gouge, and holder checked

— Gouge, holder, and machine tool checked

— Gouge, holder, and machine tool checked

Verification list — Displays a chronological list of issues and warnings.

Issues are added to the list when:

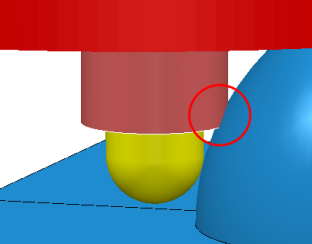

- there is a collision between the tool (or the shank, or holder) and the model.

- there is a machine tool collision.

- the machine tool cannot reach a location.

- the machine tool exceeds its limits.

Warnings are added to the list when:

- a toolpath is not verified.

- a toolpath could not be verified.

- a toolpath is verified, but the NC program has higher clearance values.

- a connection is not verified.

- the machine tool overlaps with the clearance of another component.

— Click to display the

Machine Tool Positiondialog.

— Click to display the

Machine Tool Positiondialog.

Load Issue — Select an error from the verification list and click Load issue to display the error on the model.

— Click to ignore the selected warnings. In the verification list, the selected warning changes from

— Click to ignore the selected warnings. In the verification list, the selected warning changes from

to

to

.

.

Verify — Click to refresh the verification of the NC program. This is useful when you edit the options in this dialog.

Close — Click to close the dialog.