Design Advice

The Design Advice tool identifies manufacturability concerns based on best practices for plastic injection molding, and provides recommendations to address them in Fusion.

This feature is part of an extension. Extensions are a flexible way to access additional capabilities in Fusion. Learn more.

You select a solid body and the pull direction, then click Analyze. Once the analysis is complete, the rules, results, and recommendations display.

Plastic rules

Design Advice uses the Plastic Rule assigned to the component that contains the solid body. The plastic material and the rules related to thickness and draft angle are inherited from the plastic rule.

If the component does not have a plastic rule assigned to it, you can choose to assign one before the analysis, or choose to use the default plastic rule in the design.

Summary

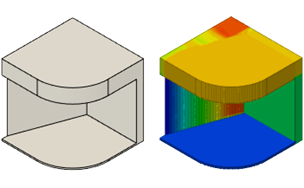

Once the analysis is complete, the Summary tab displays summary cards for the alerts it found, based on the plastic rule and pull direction:

- Thickness: Regions that fall outside the Thickness Range or exceed the Thickness Variation.

- Undercuts: Regions that will interfere with ejection from a mold, based on the pull direction.

- Draft: Regions with faces that don't meet the Minimum Draft Angle.

- Knife Edges: Regions with thin gaps that fall below the Knife Edge Threshold.

Detailed results and recommendations

A detail tab displays for each alert type that returns one or more alerts. The tab displays:

- Plastic rule details

- Plastic rule name

- Specific rules and their values

- Display controls

- List of alerts

- Recommendations to help you address alerts

You can select individual alerts to highlight them in the canvas, and ignore them to filter them out.

Modeling tools

While Design Advice is open, you can use any of the tools in the Design workspace to apply the advice and resolve alerts for specific regions.

After you adjust the geometry, you can analyze the solid body again to update the analysis. Any alerts to resolved will disappear.