Use the Drilling strategy to determine which holes to drill and how to drill them. This enables you to drill holes in several stages, only retracting a small amount after each peck.

There are several pages associated with drilling and threading strategies:

- Drilling — The main page used to define a drilling cycle.

- Retraction — Settings to control how far the thread tool retracts between pecks.

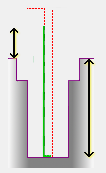

- Pecking — Settings to control how far the drill drills down the hole for each peck and retracts up the hole between pecks.

- Feed rate reduction — Settings to control the feed rate at the top and bottom of a hole relative to the feed rate for the remainder of the hole.

- Feed rate intersection — Settings to control the feed rate at the intersections of a hole relative to the feed rate for the remainder of the hole.

- Chamfer — Settings to create a chamfer with a tool larger than the hole without having to define the hole as a tapered hole. Single peck, boring, helical and profile cycles have a chamfer page.

- Draft — Settings to create a tapered hole using a tool smaller than the hole. Helical and profile cycles have a draft page.

- Profile — Settings to determine the toolpath leads, and optionally, the thickness of the final profiling pass. At each depth, the tool moves on to the edge of the hole using a circular arc lead with a straight extension, cuts a circle, and then moves back to the centre with a circular arc lead and straight extension.

- Threading — Settings for thread creation.

- Stock— Settings to select the stock model and to enter the thickness of material detected.

- Order — Settings to control the order of machining.

- Automatic verification — Settings to automatically verify the toolpath when calculating it.

For more information on the Strategy Selector dialog, see Toolpath Strategies.

The common tabs are described in common toolpath strategy pages.