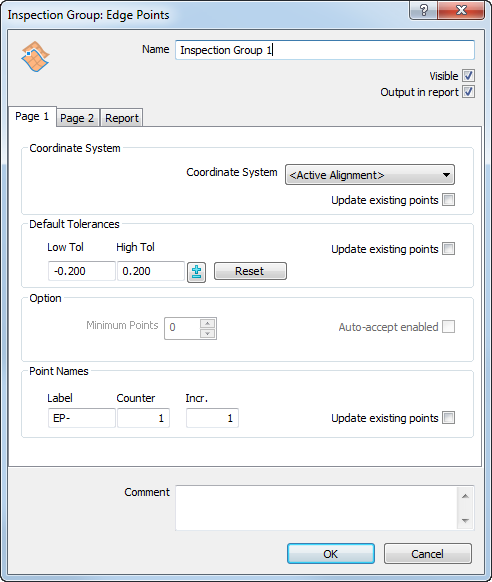

Use the Inspection Group: Edge Points dialog to specify the details of a CNC Edge Group.

To display the dialog, double-click the group's name in the Sequence Tree.

The dialog contains the following settings:

Name — Enter a name for the item. The name is used in the inspection sequence, in the Report and Info tabs, and when referencing the item in other items.

Visible — Select this check box to display the item in the CAD view.

Output in report — Select this check box to include the item in the report.

Coordinate system — Select the alignment relative to which the item's measurements are to be reported.

To specify the alignment during the inspection, select <Active Alignment>. You can then select the alignment from the Active alignment list, or by adding an Active Alignment item to the inspection sequence.

Update existing points — Select this check box to apply the selected coordinate system to items already in the group.

Default tolerances — Enter the maximum distances from the nominal surface at which points are in tolerance. Select the Update existing points check box to apply the values to points already in the group.

Select Reset to revert to the defaults specified in the Measure Parameters dialog.

Point names — Enter a Label, Counter, and Incr to control the naming of points added to the group. Select the Update existing points check box to apply the rules to points already in the group.

- Label specifies the prefix or suffix of point names in the group. Enter the percentage character (%) before the text to display it as a suffix.

- Counter specifies the first number of the point name.

- Incr. specifies the increment for the point name. For example, when Counter is 3 and Incr. is 2, the points are renumbered 3, 5, 7…

To base the labels on the name of the surface the points are projected onto, select the Use surface projected onto as point name prefix check box in the Surface Inspection page of the Options dialog.

Select the Update existing points check box to apply the changes to existing points. For example:

- If a group contains points named SP-1, SP-3, SP-4 and SP-6, and you set the Label to SP-%-Part1, the Counter to 1 and the Increment to 1, the sequence becomes SP-1-Part1, SP-2-Part1, SP-3-Part1 and SP-4-Part1.

- If a group contains SP-1, SP-3, SP-4 and SP-6 and you set the Label to %-SP, the Counter to 100 and the Increment to 20, the sequence becomes 100-SP, 120-SP, 140-SP and 160-SP.

Comment — Enter any notes and extra information about the group.

Default offset — Enter values to compensate for the thickness of the part. Positive values offset nominals towards the probe.

- Surface – enter the offset for surface point nominals. This value can be used to compensate for the thickness of the pressing (usually a positive value), or for the spark gap of an electrode (usually a negative value). The offset is normal to the surface at the probed point.

- Edge – enter the offset for the edge point nominals. The offset is normal to the surface edge at the probed point.

Select the Update existing points check box to apply the values to points already in the group. Select Reset to revert to the defaults specified in the Measure Parameters dialog.

Custom levels — By default, PowerInspect projects the inspection points onto the nearest surface. To exclude surfaces from use, select the Use custom levels check box, and click Levels. Select the Update existing points check box to apply the exclusions to points already in the group.

To specify the surfaces that can be used for this group:

- Select the Use custom levels check box, and then click the Levels button. The CAD Object Selection dialog is displayed.

- Click

to expand the folders and display the CAD level and object entries.

to expand the folders and display the CAD level and object entries.

- Select the check boxes of the entries you want to make available for inspection; deselect the check boxes to exclude them from inspection.

- Click OK to save your changes and close the dialog.

- Select the Update existing points check box to apply the level selection to points already in the group.

Edge — Select this option to inspect a flat edge.

Hem edge — Select this option to inspect a rounded edge, and enter the inner radius of the hem in Radius box.

Report — Select this tab to specify the layout settings of the inspection group in the report: Select:

- Points list to display the list of points in the group.

- Repeat CAD View on each page if the group contains a

CAD View Report item and you want to display the CAD view on each page of the group's results. If the group contains:

-

- no CAD View Report items, selecting the check box has no effect.

- one CAD View Report item, the CAD view appears on each page of the report in which the group's data is displayed. Each CAD view displays only the points listed on that page.

- multiple CAD View Report items, each CAD view displays the points that precede it in the group.

- Tolerance plot to display the tolerance for each point compared to the in-tolerance range.

- Statistics table to display the statistics for the group.

- Distribution chart to display the tolerance distribution for the group.

- Save as default to use these layout settings as the defaults for new groups in the report.

-

Click OK to close the dialog and save your changes.