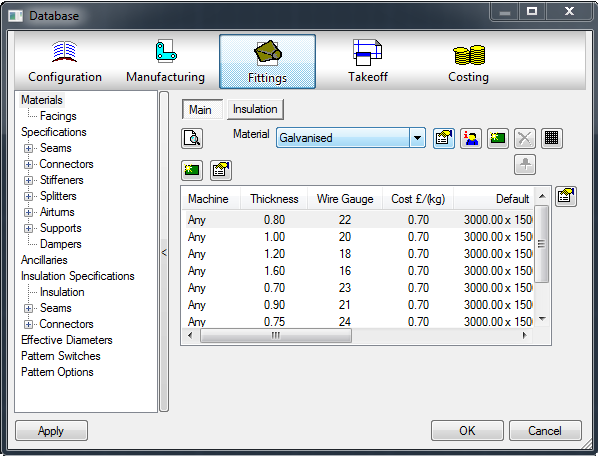

The materials database allows the user to enter, edit or delete materials, gauges (thickness) and stock sheet sizes that can be assigned to fittings and parts to be manufactured.

On the Database dialog, click Fittings

Materials to display the Materials options.

Materials to display the Materials options.

The Material Database is organized into 2 tabs: Main and Insulation. Both work the same way, but allow for the separation of Manufacturing materials and Insulation materials.

To create a new material:

- Click

.

.

A prompt asks if the new material is to be based on the currently displayed material.

- Click Yes to use all of the thickness and sheet sizes of the currently selected material.

- Change the thicknesses and sheet sizes as needed for the new material, or accept the current settings.

- Next you are prompted to assign the current Specifications to the material, if applicable.

- Click in the Name field to change the name of the new material from Untitled to the new name.

- Click the

Filter Out Non-User Data button to select data to be hidden from displayed properties in dialogs and in the model.

Filter Out Non-User Data button to select data to be hidden from displayed properties in dialogs and in the model.

For more information, see Filter Out Non User Data..

- Click

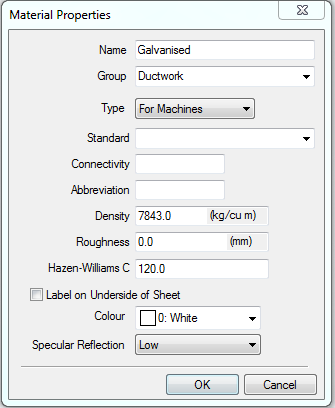

to display the Material Properties dialog.

to display the Material Properties dialog.

- Configure the Material Properties dialog as needed for the new material, and click OK.

The Material Properties dialog lets you specify Groups, Standards, and other material information that will be used in reports. If you are using pressure in a Design Line, the Material Properties dialog also lets you specify airflow information.

The following options are available on the Material Properties dialog.

Group: Can be used to group materials together into groups, such as ferrous and non-ferrous. When data is entered, it is stored for future selection on other materials in the drop-down boxes.

Type: The Type property changes the behavior of the material gauge section on the content. The available choices are Pipework, For example, when the Type is set to Pipework, the Gauge drop-down selection list and content display the material specification. The Type property also acts as a filter when assigning the material to the items. For more information, see Material Type Property.

For Machines: When selected, this material is displayed in the Installed Machines Tools dialog so that Lead Ins, Kerf Values etc can be applied to the material. When not selected, any items assigned to this material will not be nested.

Standard: The Standard field allows extra information to be attached to the material which would show the material as being of a certain grade, such as a British Standard etc. When data is entered, it is stored for future selection on other materials in the drop-down boxes. This is also available as a print object.

Connectivity: A material can be assigned a connectivity property. This is to be used in conjunction with the "Coupling" pattern in order to be able to attach different materials to one another. This is used within the connected drawing mode of quick takeoff, and in CADmep for controlling appropriate material connections.

Abbreviation: An abbreviation for the material name can be entered here. These abbreviations are typically only 3 or 4 characters long. For example, an abbreviation such as "STLS" is generally used on reports, to minimize the amount of data on a report.

Density: Density is used to calculate the weight of a part from its thickness and size. In metric units, the density is measured in kg/m3, whereas in imperial the units are lb/ft3.

Roughness: Roughness is a value that is applied to a material so pressure drops can be accurately calculated on pipe work. This is also available as a print object.

Hazen-Williams C: Specifies the Hazen-Williams coefficient used in calculating friction loss in ducts and pipes.

Label on Underside of Sheet: This property is used to alter the arrow indicator on the labels. The setting for flipping the sheet is done elsewhere in the database. See the "Part Labels on Inside" setting in Pattern Switches.

Color: A color can be applied to the Material for use in Takeoff, Design Line, and CADmep drawings. If Use Material Color is used in Takeoff, the items made with this material will carry that color.

Specular Reflection: Specular reflection is the mirror-like reflection of light (or of other kinds of wave) from a surface, in which light from a single incoming direction (a ray) is reflected into a single outgoing direction. This can be emulated using OpenGL and applied to the material.

Owner Information is used to assign materials to Product Listed and Content Driven Items.

Owner Information is used to assign materials to Product Listed and Content Driven Items.