This section describes how to program the counterbored hole on the rear of the part.

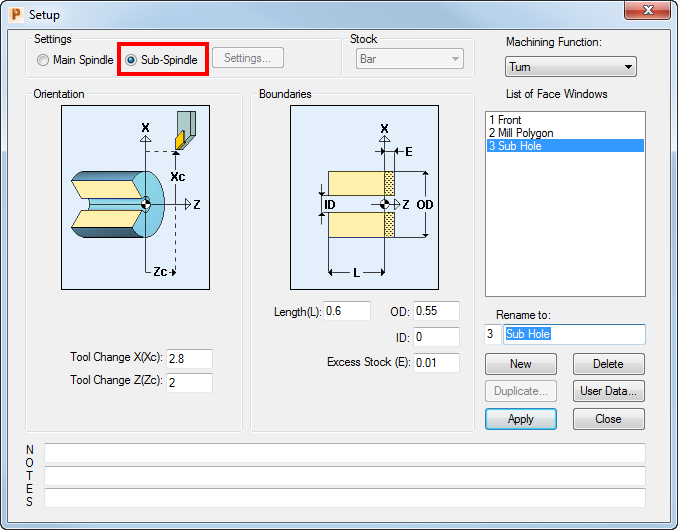

As this toolpath will be machined using the sub-spindle, you first need to create a new Face window.

- Select View > Setup and then click New.

- Complete the Setup dialog, as shown, remembering to select Sub-Spindle:

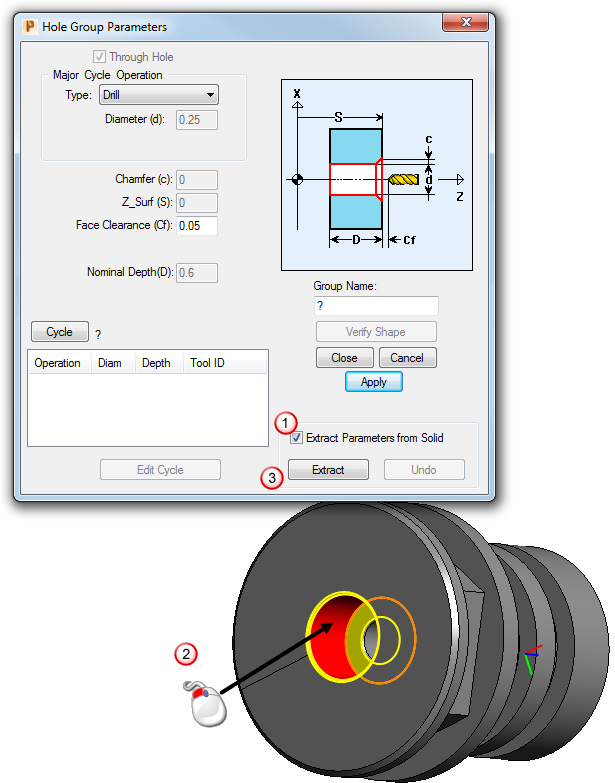

- Select a color for the toolpath from the Color Palette, then click the

New Hole Group button to display the

Hole Group Parameters dialog.

- Complete the dialog as shown, by selecting the

Extract Parameters From Solid option, selecting the hole in the Solids window, and then clicking

Extract.

If you are not using a solid model file and so cannot extract the hole values automatically, you need to enter the values shown in the red boxes above directly into the Hole Group Parameters dialog.

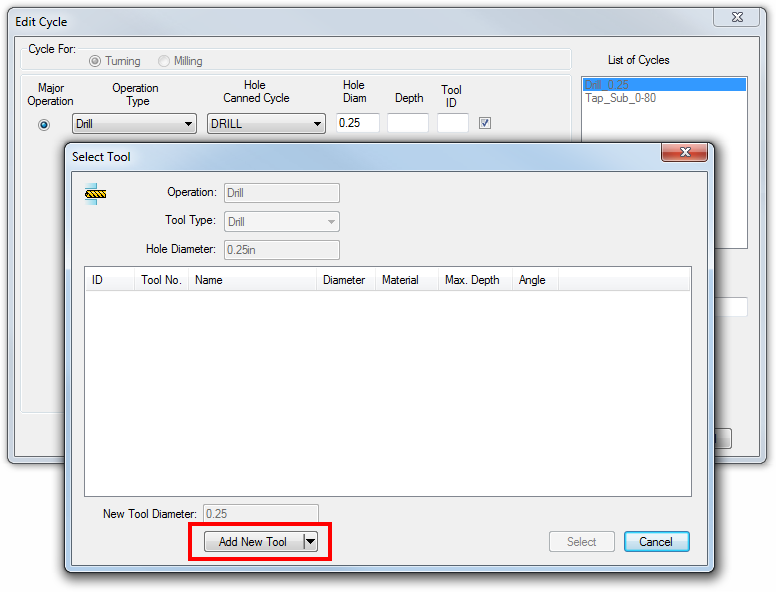

- When you click Extract, the Select Cycle dialog is displayed.

- As no suitable cycle already exists, click Add New Cycle to display the Edit Cycle dialog.

- Click

Select Tools to display the

Select Tool dialog. As no suitable tool exists in the Tools database, click

Add New Tool to add a new tool:

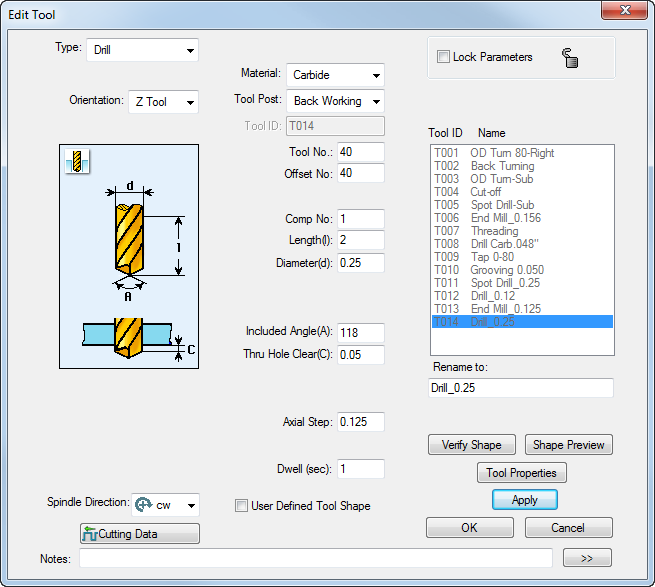

- Complete the

Edit Tool dialog as shown, then click

OK.

- Select

OK on the

Edit Cycle dialog to return to the

Hole Group Parameters dialog, then click

Close.

PartMaker displays the drill toolpath in the 2D window: