Swarf is a powerful technique. Unfortunately, in a five-axis simultaneous situation, there are many different correct answers to the swarf problem. FeatureCAM attempts to pick an intelligent answer, but sometimes picks a different answer than what you had in mind. For instance, a single plane can be swarfed in the U direction or the V direction.

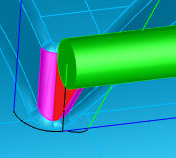

In the image below, the feature consists of two magenta surfaces and a red surface. The swarf correctly cuts the required edge of the magenta surfaces, and then (mathematically, correctly) cuts an incorrect edge of the red surface.

There are several things you can try:

- Break the feature into many features (at the limit, you might have one swarf feature per surface). In this case, you may end up with three features.

- In a turnmill document, you may sometimes get the required answer by choosing to cut the feature with an X tool. This is the case for a single planar surface that cuts the U direction instead of the V direction.

- Construct a ruled surface and use it as the part surface(s).

- Additional surfaces can sometimes help

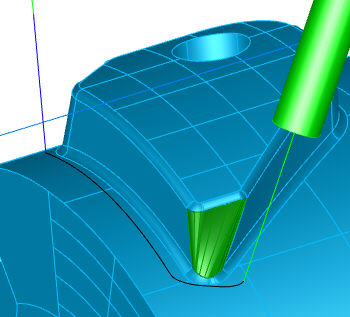

FeatureCAM select the correct face. In this picture, the previous hint was also used (the green ruled surface replaced the three faces of the solid).

Eliminate any fillets in the model, and use a ball-end of the appropriate size.

- Decrease or increase the Tolerance. Because the surface(s) in between its edge curves may not be perfectly ruled, swarf is dependent on the tolerance setting.

- Often, the tool is upside down of the required toolpath. Select Reverse tool axis on the Strategy tab.

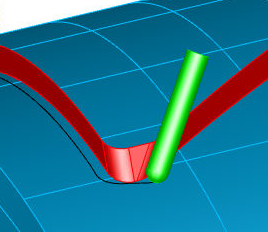

- In cases like the above, the floor of the swarf must not be touched. This is difficult to do, especially with a flat-end tool. You may include the floor as a Check surface, but you may not get the complete toolpath. In this situation, you can get close by using Multiple Cuts and a small Z-increment. You may also use a slightly negative Check allowance.

- Increase the Degouge tolerance. The Tolerance value controls the accuracy of the tessellation: curved surfaces are first flattened out to triangles, and the triangles are then machined. The Degouge tolerance specifies how far FeatureCAM can gouge the triangles to get a better, smoother toolpath.