Import Dynamic Simulation motion loads

Use the Motions Loads Analysis option to import occurrence-based motion loads created in the Dynamic Simulation environment. Only parts that are unique bodies, and meeting the following criteria, are valid for motion load transfer:

Motion Load Criteria

- The part must not be welded to another part.

- Only top-level part occurrences and flexible subassemblies are candidates for Export to FEA. Export to FEA is done in the Dynamic Simulation environment.

- The analysis is limited to a single part occurrence and a single time step nominated in Dynamic Simulation. Other bodies are automatically excluded. All boundary conditions are imported from Dynamic Simulation.

- The time step is expressed in seconds. Include a leading zero. Scientific notation can be used in extreme cases.

- Multiple simulations can be made referencing the same occurrence and using the same time step.

- Assembly features are considered when conducting an isolated stress analysis simulation.

Incomplete definition messages

- If the Motion Loads Analysis option is selected and no component is specified, you are prompted to select a component.

- If no time step is specified, the drop-down list displays No time step selected.

- If during a dynamic simulation update, the specified component has insufficient faces defined, the occurrence is removed from the export list. You are prompted to select a new part or complete the load definition in dynamic simulation.

First, export the loads from Dynamic Simulation environment. Then, in the Stress Analysis environment, specify that motion loads are included in the simulation. Separately export motion loads for each part.

Analyze motion loads for a part in an assembly

For a new simulation, on the ribbon, click Stress Analysis tab

Manage panel

Manage panel  Create Simulation

Create Simulation .

.For an existing simulation, in the browser, right-click the simulation node and click Edit Simulation Properties

.

.The Simulation Properties dialog box displays.

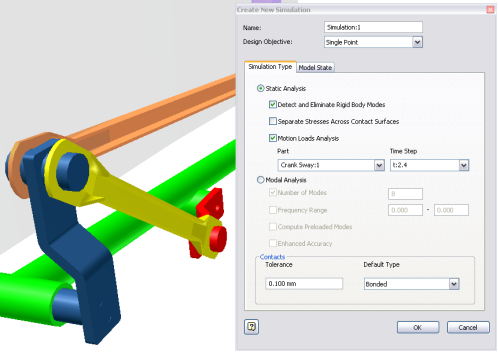

In the Simulation Properties dialog box, Simulation Type tab, check the option Motion Loads Analysis. More controls are enabled.

Select the Part from the available list.

Select the Time Step from the list of time steps that are generated in Dynamic Simulation.

Click OK.

If appropriate, A new simulation is created for the selected component. All appropriate loads related to the occurrence populate the Loads folder in the browser.

Complete the simulation definition.

For an existing simulation, modify any simulation parameter as necessary.

Run the simulation.