Sample files for use with the examples are available from the Simulation downloads page.

Expand the downloaded ZIP archive into a convenient directory from which to run Local Simulation inside the numbered directories.

Problem description

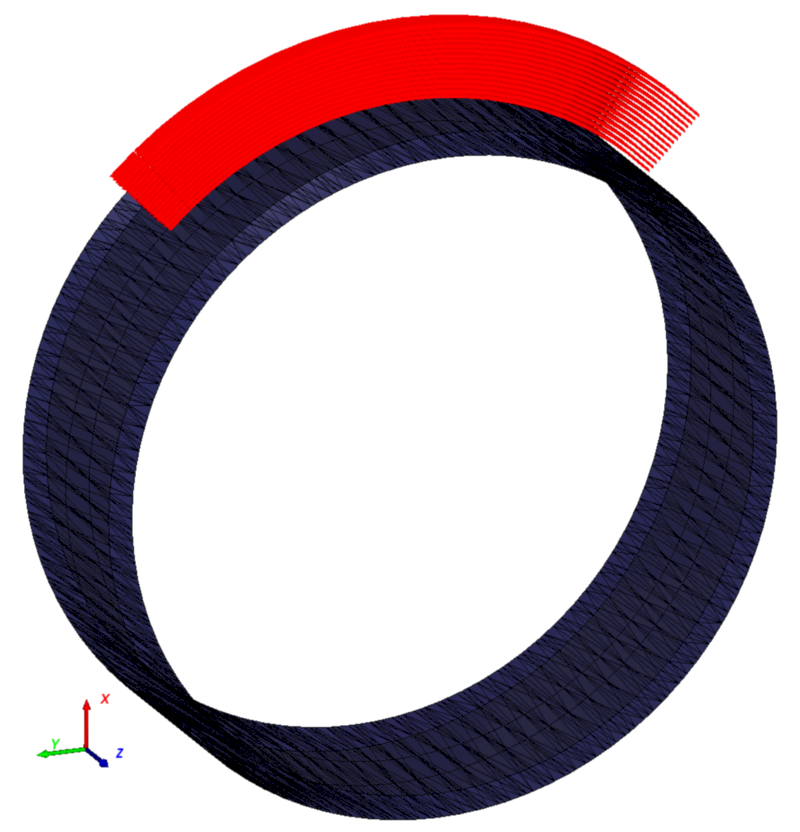

This example simulates the multi-axis Directed Energy Deposition (DED) construction of an eight-bead-wide, 15-layer-high, 316L-stainless-steel component on a tubular 316L-stainless-steel substrate. While multi-axis DED laser path files (LSR) can be imported and viewed in the Simulation for Netfabb software, the simulations must still be performed at the command line.

The example resources include the LSR file to describe the 3D laser paths. Also included is a Scilab script, gen-path-tube-clad.sce, to generate the file.

Multi-scale DED example geometry showing tubular substrate (blue) and laser path (red)

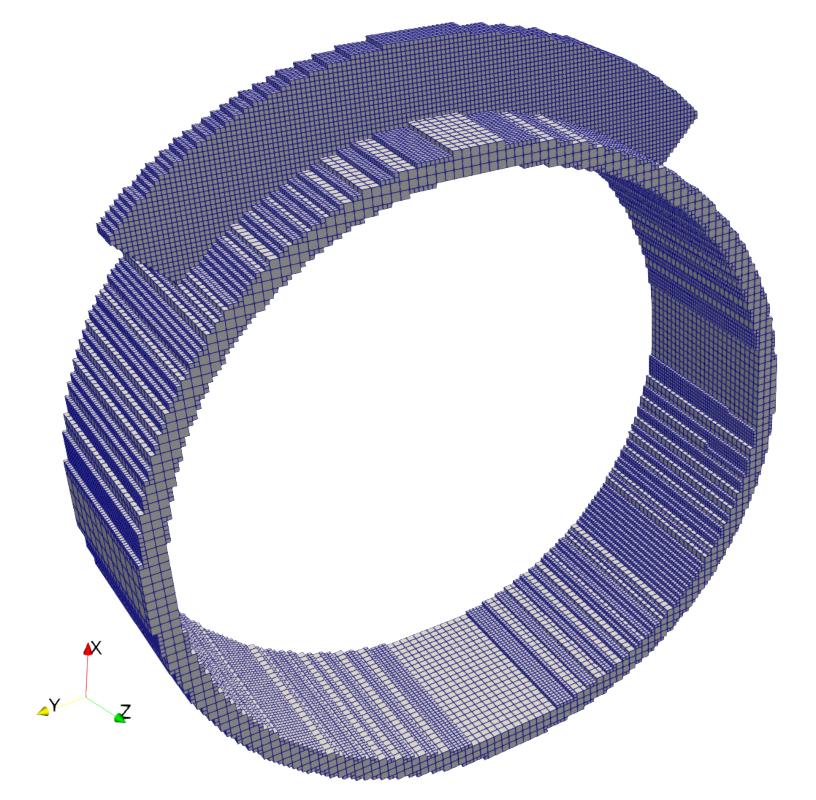

The radius of the melt pool is 1 mm, its power is 800 W, and the translation speed is 10 mm/s. The hatch spacing between the eight beads is 1 mm. The ambient temperature during the process is 25 °C. The substrate is constrained as simply supported on the -z side using the *SBC3 card, along with a spring fixture to model the tube being held in the chuck of the machine using the *FISR card. The springs are released during the cooling step near the end of the analysis using the *RAMP card. The thermal and mechanical response of this process is to be calculated using Netfabb Simulation with adaptive meshing.

Multi-scale DED mesh