Correctively distort a mesh part to compensate for laser overpenetration

Whenever working with laser machines, it is likely that the first layer of a model is printed thicker than the following. This is due to the laser energy penetrating deeper into unrendered powder than into powder on top of rendered material. For small parts, this thickening of downward-facing surfaces can constitute a significant distortion. To counteract this, any downward-facing sections of the geometry are shifted upwards so that, after exposure, the rendered surfaces end up in their intended positions.

Whenever working with laser machines, it is likely that the first layer of a model is printed thicker than the following. This is due to the laser energy penetrating deeper into unrendered powder than into powder on top of rendered material. For small parts, this thickening of downward-facing surfaces can constitute a significant distortion. To counteract this, any downward-facing sections of the geometry are shifted upwards so that, after exposure, the rendered surfaces end up in their intended positions.

Z-compensation is also available as a repair action as well as a slice-processing action.

- Select the part.

- From the main menu, choose .

- Adjust values to your machine's specific requirements.

- Click OK.

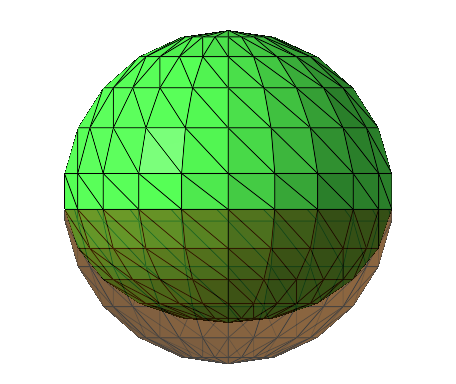

An exaggerated example of Z-compensation. The brown transparent section indicates the original shape.

Recommendations

Z-compensation works best with regular triangles. It may produce undesirable results when the triangles are long and narrow, especially along small creases or protrusions in the part's shape. If that happens, experiment with the Preprocessing setting on and off, and try remeshing the offending sections. To save on processing time, apply the remeshing only to downward-facing areas using to catch downskin triangles only. Use the + and - keys to grow and shrink the generated selection to include enclosed but not selected triangles.

Z-compensation reference

Parameters

- Manage Setting: With this section you manage value presets for Z-compensation.

- Translation: Shift geometry up by this amount. This is the distance the geometry is displaced at most: For every point, the shift applied to it is scaled by the local surface angle against the horizontal. The steeper the angle, the smaller the shift. If you need, you can type larger values in the box than the range the slider covers.

- Preprocessing: In very special cases of very noisy meshes, this option can improve results. Generally, for all but the most noisy meshes, this option should remain off.

- Keep/Remove original part: Z-compensation generates a new part with the compensated geometry. Select whether to keep the original. Useful for follow-up mesh comparison.

Caveats

- The correction is applied to the triangle nodes. Depending on the triangulation of the surface, this can introduce noticeable distortion in the scale of shift and triangle size. To mitigate this, refine the triangle mesh, or remesh the part outright to a smaller triangle edge length on average or at least along susceptible edges.

- When you process objects with angled surfaces that terminate in sharp edges approaching the horizontal, these edges can get bent upwards. To mitigate this, try to avoid part orientations where sharp edges approach the horizontal, or try to avoid sharp edges entirely.

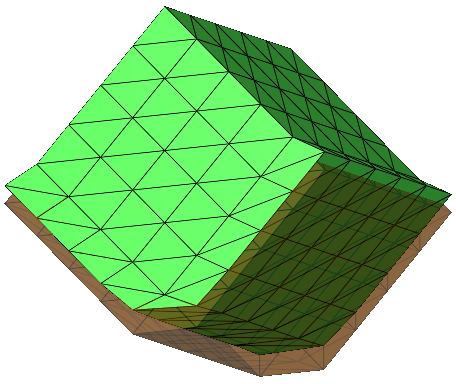

An exaggerated example of distorted edges. The brown transparent section indicates the shape before Z-compensation.