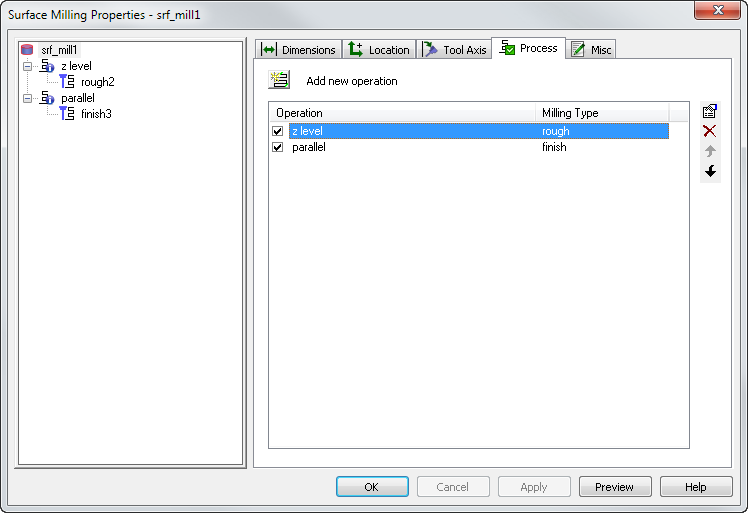

The Process tab lists the operations that are included for milling the feature in the order they happen. You can remove operations by deselecting them. This enables you to customize operations and then turn them off to reduce screen clutter when working on subsequent operations.

The buttons have these functions:

New operation

New operation

Select a machining strategy:

Finishing Strategies

- Parallel - toolpaths that are parallel to the X or Y axes.

- Z level finish - toolpaths that are parallel to the XY plane.

- Isoline milling - toolpaths that follow the rows or columns of individual surfaces.

- 2D spiral - Toolpaths that move in a spiral toward or away from the center of the part. Stepover is constant from the top view.

- 3D spiral - Toolpaths that move in a spiral toward or away from the center of the part. Stepover is constant in 3D.

- Radial milling - toolpaths that move out radially from the center of the feature.

- Flowline milling - toolpaths that follow the rows or columns of a flowline surface which are then projected onto the part.

- Between 2 curves - toolpaths that are created between two specified curves.

Roughing Strategies

- Z level rough - toolpaths that are parallel to the XY plane.

- Plunge roughing - toolpaths which remove large amounts of material from a component through a series of vertical plunging movements.

- Parallel - toolpaths that are parallel to the X or Y axes.

Specialized Strategies

- Horizontal + Vertical - machine steep and shallow regions using different techniques.

- Corner Remachining - A remachining technique used to clean up corners that occur between non-tangential surfaces.

- Pencil milling - a single clean-up pass for corners.

- 4-Axis Rotary - used in turnmill to machine round surfaces with an X tool.

- Swarf - toolpaths are cut using the side of the tool. The tool is in constant contact with the surface.

- 5-Axis Trim - toolpaths that are along the edges of surfaces. There is the option to cut on the inside or outside edge of the surface.

For more details on these options, see operations overview.

Move item up changes the order of operations in the milling feature by moving the selected operation up one place in the list.

Move item up changes the order of operations in the milling feature by moving the selected operation up one place in the list.

Move item down changes the order of operations in the feature by moving the selected operation down one place in the list.

Move item down changes the order of operations in the feature by moving the selected operation down one place in the list.

Delete operation removes an operation from the feature. You can disable an operation instead by deselecting the operation. The check box, when set, includes that operation in the feature.

Delete operation removes an operation from the feature. You can disable an operation instead by deselecting the operation. The check box, when set, includes that operation in the feature.