Natural Ventilation

Air movement in natural ventilation applications is generally the result of density gradients caused by temperature variations throughout the structure. Fans and other mechanical devices may be present, but do not dominate air movement. Many structures exhibit the combined contributions of ambient air passing through doors and windows with buoyancy-driven natural ventilation.

Application Examples

Natural Flow and Thermal Phenomena, typically involving buoyancy-driven flow:

Natural ventilation in municipal buildings:

Condensation and Thermal Stratification in Atria:

Modeling Strategy

Primary modeling considerations for natural ventilation models include:

- Simplify the geometry to remove extraneous features. Simplify or rebuild parts to remove detail that is not relevant to the simulation.

- The model must contain an air volume within the device. This is a consideration because the physical model probably does not contain one. Autodesk® CFD automatically creates an internal volume if the geometric model is "air tight." If not, modify the CAD model to close any gaps or use the Void Fill tool to create the volume on the Autodesk® CFD model.

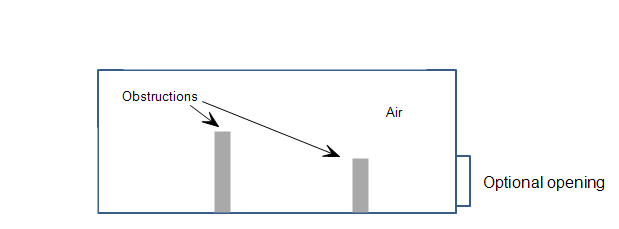

Internal flow only

If the intent is to simulate the natural ventilation within the enclosure, model the structure, relevant obstructions, and internal air.

If the structure has openings, a good practice is to extend the openings in the CAD model to ensure enough space between the boundary conditions and the internal flow.

- This is useful for flow-only analyses, but is essential when temperature boundary conditions are applied to openings. This practice ensures adequate distance between the opening and the neighboring walls whose temperatures are not known.

- Extend the opening at least the hydraulic diameter of the surface.

Combined internal and external flow

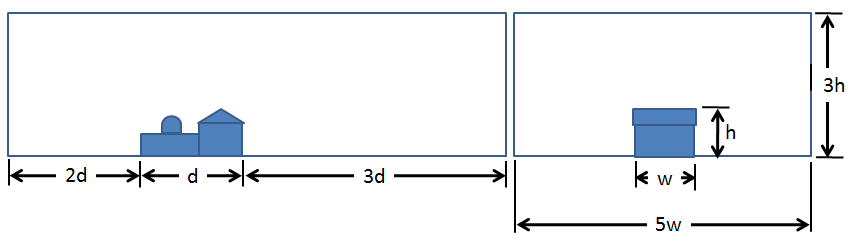

If the structure is vented, and wind loading is a consideration in addition to the natural ventilation within the structure, create a volume that surrounds the structure:

- Add this volume either in the CAD model or in Autodesk® CFD with the External Volume tool. (We recommend creating it in the CAD model so the volume can be coplanar with the ground-plane of the structure.)

- Build the environment geometry using these recommended relative dimensions:

These items and several more are presented in detail in the AEC Geometry Modeling topic...

Materials

Assign the Air material to all air regions.

Change the Environment setting to Variable. This allows the properties of air to vary with temperature, and for air movement to occur as a result of temperature gradients.

The default air properties are set for 68 °F. If the operating temperature is greater than 90 °F or less than 50 °F, modify the Scenario Environment temperature to the appropriate value. This ensures the air density is appropriate for the operating conditions.

Several other material types are commonly used in AEC applications:

- Solids

- Internal fans

- Distributed Resistances

Click here for more about materials in AEC applications...

Boundary Conditions

Internal Flow only

Apply a Total heat generation boundary condition to components that dissipate heat.

To simulate heat transfer to the surroundings, apply a Film Coefficient boundary condition to the external surfaces. The value depends on the air that surrounds the physical device:

- If the air is still, use a value of 5 W/m²K.

- If the air is moving, use a value of 20 W/m²K.

- Use a Reference Temperature = ambient temperature

If the structure has openings, specify a Static Gage Pressure = 0 on each.

If there are multiple openings, specify a Temperature boundary condition on each. Specify the ambient temperature value.

If there is only a single opening, specify a Film Coefficient boundary condition to the opening. Use 5 W/m²K as the value, and Use a Reference Temperature = ambient temperature.

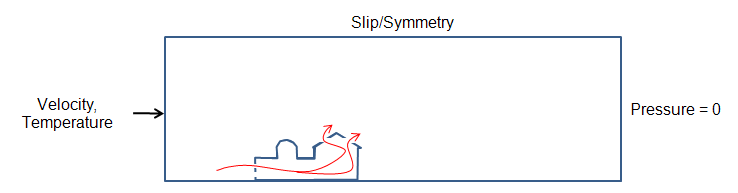

Combined internal and external flow

Flow passes in and out of the building. It is driven by the wind, buoyancy forces, and internal fans.

- To define the inlet of the air volume, assign the wind speed as a Velocity boundary condition.

- To define the outlet of the air volume, assign Static Gage Pressure = 0.

- If the air region simulates a free-space environment (not a wind-tunnel), assign Slip/Symmetry to the top and sides of the region. (Do not specify a condition on the ground plane, because the air does not physically move along the ground plane.)

- Do not assign boundary conditions to windows and doors. Air flows in and out of the building based on the effects of wind and buoyancy.

Mesh

A basic guideline for a high-quality analysis model is that the mesh distribution be sufficient to resolve the flow and temperature gradients efficiently. In regions where the flow circulates or experiences large gradients (such as in wakes, vortices, and separation regions), a finer mesh is required.

For most models, use Automatic Sizing to define the mesh distribution. It may be necessary to locally refine the mesh on geometric features that are highly detailed. For more information about Mesh Autosizing and model preparation...

In some cases, it may be necessary to adjust the Minimum Refinement Length to reduce their effect on the overall mesh count.

To locally refine the mesh in high-gradient flow regions:

Adjust the mesh distribution on geometric volumes and surfaces.

If there are no appropriate geometric features in a particular region, create a mesh refinement region:

- Add one or more volumes in the CAD model.

- Create a Refinement Region from the Meshing task.

Running

On the Physics tab of the Solve dialog:

Flow = On

If solving for heat transfer:

- Heat Transfer = On

- Specify a Gravity vector. (Use Earth, and set a direction.)

On the Control tab of the Solve dialog:

- Iterations to run = 750

The specified number of iterations, 750, is the maximum number of iterations that will run. (This has been found to be sufficient for most mechanical ventilation simulations.) Autodesk® CFD stops the solution when either 750 iterations have been completed or when the solution reaches convergence, whichever comes first. If heat transfer and Automatic Forced Convection are enabled, Autodesk® CFD automatically solves for the temperature distribution after the flow solution is complete.

Additional Solver Capabilities

- To simulate surface-to-surface radiation and solar heating, enable Radiation. Models with very high component temperatures or open fires (such as for smoke visibility) are good applications of radiation. To enable Radiation, check the Radiation box on the Physics tab. For more about Radiation...

- To simulate solar heating (either diurnal or steady-state), enable Radiation, and click the Solar heating button. Specify the time, date, location, and direction to define the solar analysis. For more about Solar heating...

- Once the box is checked, you can set up solar heating parameters (time, date, location, direction) in the “Solar Heating” dialog.

- To simulate mixing, especially for smoke analyses and chemical contaminant studies, enable the General Scalar solver. (Click the Advanced button on the Physics tab.) For more about Scalar Mixing...

- To simulate condensation of moist air, enable the Humidity solver. (Click the Advanced button on the Physics tab.) For more about Humidity...

- To compute the level of Thermal Comfort, click the Result quantities button on the Control tab, and check the Thermal comfort box. For more about Thermal Comfort...

- To compute the visibility through smoke, click the Result quantities button on the Control tab, and check the Smoke visibility box. For more about Smoke Visibility...

Results Extraction

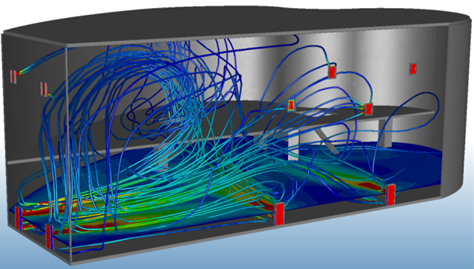

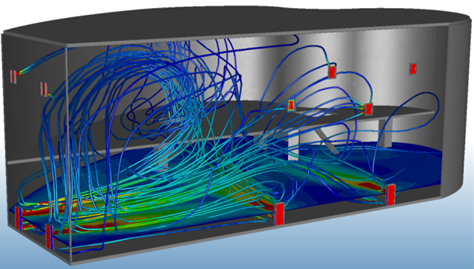

- Use Results Planes and Iso Surfaces to visualize the flow in and around the fixture.

- Use Particle traces to visualize air movement.

- Display temperature directly on parts and use Results Parts to extract quantitative temperature data.

- Use the Decision Center to compare results from multiple scenarios. Save summary images and create summary items, and evaluate the results in the Critical Values table.

For more general information, use the extensive collection of results visualization tools to extract flow and thermal results.