Simulation for manufacturing

Simulation in the Manufacture workspace enables you to visualize and validate various manufacturing processes, including milling, drilling, turning, inspection probing, cutting, and direct energy deposition (DED) additive manufacturing. Simulation consists of two key aspects: animation and verification. In addition, simulating with a machine, also known as machine simulation, is available for milling setups with a CNC machine.

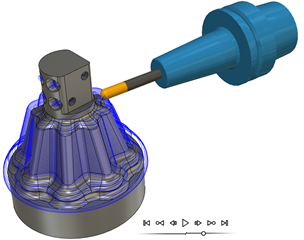

Animation

The animation aspect of simulation visually represents the tool's movements along the defined toolpaths. It provides a dynamic display of how the tool interacts with the stock material during the manufacturing process. Also, it highlights any collisions that may occur between the tool and the stock. By observing these visual representations on the canvas, you can gain a better understanding of the tool's path and the change in the stock material.

Verification

The verification aspect of simulation ensures the accuracy and integrity of your manufacturing process. It performs background checks, such as collision detection, to identify any potential issues that may occur during the actual machining process. This verification process helps validate the feasibility and safety of your manufacturing operations.

Simulating with and without a machine

You can simulate with a machine and simulate without a machine, and each option serves a specific purpose and provides unique benefits. The table below provides a comparison between the two, highlighting their suitability for different setups, the level of accuracy in the representation, the focus of the simulation, and what information each one uses.

| Simulate with a machine | Simulate without a machine |

|---|---|

| Specifically available for milling setups with a CNC machine. | Suitable for milling, turning, and cutting setups. |

| Offers a more accurate representation of the manufacturing process, but it may take longer to load and simulate. | Provides a quick and basic simulation for initial visualization and assessment purposes. |

| If the machine definition has a linked machine model, the simulation incorporates machine movements in addition to tool and stock visualization and collision detection. | Focuses on tool movements, stock visualization, and collision detection. |

| Uses kinematics information from the machine definition and post processor, providing a more accurate representation of how the machine and tool move. | Does not use information from the machine or post processor, resulting in a less accurate representation of how the machine and the tool move. |

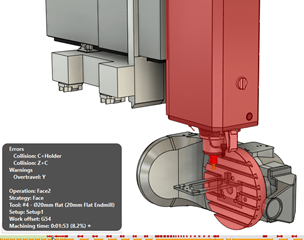

Checking for simulation issues

Simulation includes various checks to identify potential issues that may affect the manufacturing process. Fusion detects and reports the following simulation issues:

Collisions that occur within the machine. This includes collisions between the machine and the stock, between the machine and any fixtures, and between the different aspects of the machine itself.

Collisions that occur within the machine. This includes collisions between the machine and the stock, between the machine and any fixtures, and between the different aspects of the machine itself. Overtravel of machine axes, where the simulated toolpath goes beyond the physical limits of the CNC machine.

Overtravel of machine axes, where the simulated toolpath goes beyond the physical limits of the CNC machine. Retract and reconfigure of the machine, where the simulated toolpath is automatically modified to avoid an overtravel.

Retract and reconfigure of the machine, where the simulated toolpath is automatically modified to avoid an overtravel. Rapid moves of the machine's tool or table that causes the tool to cut into the stock.

Rapid moves of the machine's tool or table that causes the tool to cut into the stock.