Parallelism

Like flatness, typically only a portion of the part has a Parallelism tolerance.

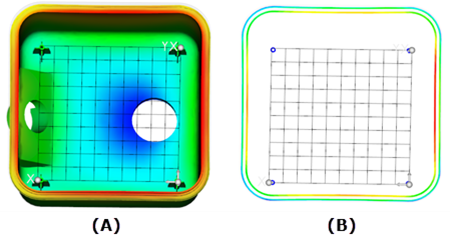

Parallelism relates to two planes. An anchor system is set on one plane, that must be parallel, so the anchor's XY-plane defines one of the parallel planes. Therefore the Z-direction is used to measure the parallelism tolerance, on another plane. Isolating the area that has the parallelism tolerance with layers or a path plot is usually the easiest way to interpret the results. In the figure below, the screw bosses form one parallel plane. The sealing surface forms the second plane. The tops of the screw bosses (where the anchors are) and the sealing surfaces are isolated on a lay. The deflection scale was modified so the location of the minimum and maximum deflections on the sealing surface is easily identified.

A = Anchor plane on screw bosses to measure parallelism of the sealing surface

B = Sealing surface and screw bosses isolated to layers and results scaled to determine maximum and minimum values