Use the Model Rest Profile strategy to eliminate large terraces. Area clearance strategies carry out efficient volume removal with a large tool and then rest area clearance strategies use a smaller tool to machine the model profile at each intermediate Z height of the model. this machines areas the large tool could not reach, such as pockets and corners. This reduces the degree of tool overload and provides a more constant material removal rate for subsequent finishing operations.

This is easier to see looking at a ViewMill simulation.

If you start with an area clearance toolpath:

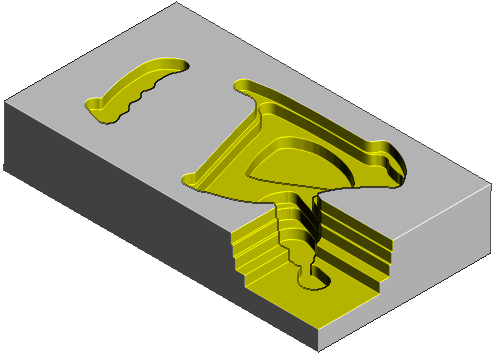

A model rest profile area clearance toolpath, based on this area clearance toolpath, gives:

There are several pages associated with the Model Rest Profile strategy:

- Model rest profile — The main page used to choose the settings to machine a model using a rest profile strategy.

- Rest — Settings to define rest machining.

- Step cutting — Settings to define in-line rest roughing. This minimises terracing when creating area clearance toolpaths with a large stepdown. This is available when you select a Stepdown of Automatic.

- Cut distances — Settings to control the number of profile cuts.

- Wall finishing — Settings to perform a Final Stepover which is different from the normal stepover.

- Unsafe segment removal — Settings to remove small toolpath segments.

- Flat machining — Settings to machine flat areas on the model.

- High speed — Settings for the smoothing options to avoid sharp changes in tool direction when high speed machining.

- Order — Settings to control the order of machining.

- Approach — Settings to control how the tool approaches the path.

- Automatic verification — Settings to automatically verify toolpaths on creation.

The remaining pages are common toolpath strategy pages.