Workflow: Setting up a part using probing

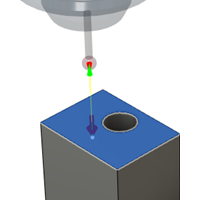

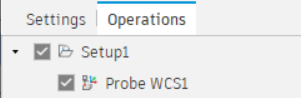

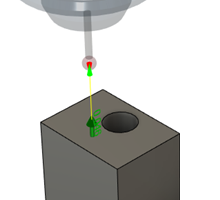

The Probe WCS ![]() strategy lets you use probe cycles on your CNC machine to locate stock, locate machined features from previous operations, and update the coordinate system defined in the setup (WCS Offset) based on the results. The inspection results can be imported into Fusion:

strategy lets you use probe cycles on your CNC machine to locate stock, locate machined features from previous operations, and update the coordinate system defined in the setup (WCS Offset) based on the results. The inspection results can be imported into Fusion:

From a machine-generated results file if a live connection is not available, or

In real-time using a live connection between Fusion and the CNC machine.

Note: Real-time inspection results are available for partial and full holes and bosses, single surfaces (including those at an angle), corners, and channels.

Import from a machine-generated results file

Generate a Probe WCS operation.

Note: In the Probe WCS dialog, ensure that the Print Results checkbox is selected.

Note: In the Probe WCS dialog, ensure that the Print Results checkbox is selected.Post process the Probe WCS operation to create NC code, and then run the NC code on the CNC machine fitted with a probe.

(Optional) Save the inspection results as a report.

Import in real-time using a live connection

This feature is part of an extension. Extensions are a flexible way to access additional capabilities in Fusion. Learn more.

Generate a Probe WCS operation.

Post process the Probe WCS operation to create NC code, and then transfer the NC code to the CNC machine fitted with a probe.

Import the inspection results in real-time as the NC code runs on the CNC machine.

(Optional) Save the inspection results as a report.