Probe WCS strategy

The Probe WCS ![]() strategy creates a probing operation to locate stock and features and update the work coordinate system defined in the setup (WCS Offset) using probing cycles (macros) on the CNC machine. Inspection results can be imported from a machine-generated results file or imported in real-time using a live connection between Fusion and the machine.

strategy creates a probing operation to locate stock and features and update the work coordinate system defined in the setup (WCS Offset) using probing cycles (macros) on the CNC machine. Inspection results can be imported from a machine-generated results file or imported in real-time using a live connection between Fusion and the machine.

Checking the position and size of a part against specified tolerances helps you to know whether the part is loaded correctly and is the correct size before machining it. If measurements exceed the acceptable tolerances, the CNC machine can be instructed to stop with a message. Using probing to refine the coordinate system also improves repeatability compared to doing it manually.

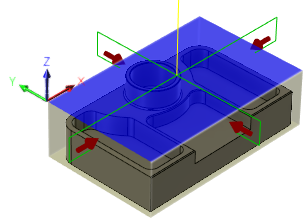

Example of a Probe WCS operation on a stock model.

The Override Driving WCS parameter in the Probe WCS dialog lets you control which coordinate system drives the probe. When selected, the probe is driven from a different coordinate system (WCS Override) to that defined in the setup (WCS Offset).