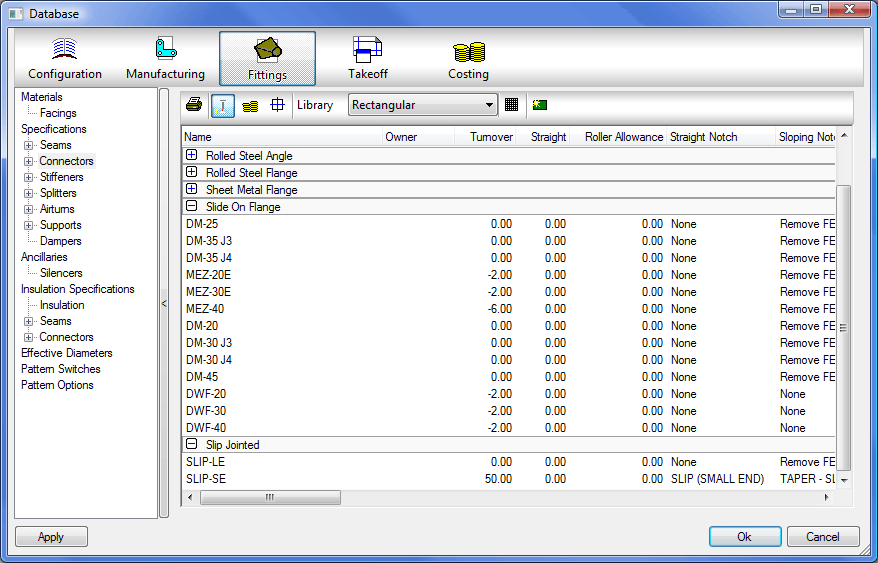

This table in the database defines the various types and allowances associated with the connectors, which are used to join two items together. There is no limit to the number of connectors that can be defined in the software. Connectors are separated into three separate connector types.

Connectors are an integral part of every item and define the method for joining one item to the next. Each open end of a pipe, fitting or equipment usually has connectors assigned. Third-party supplied objects can have connectors assigned through the Object Wrapper utility. Connectors are sub-divided into Rectangular, Round and Oval libraries. Each library may be further broken into groups of similar connectors. Pipe work connections are defined from the Round library. Connectors are auto attached to products through specifications.

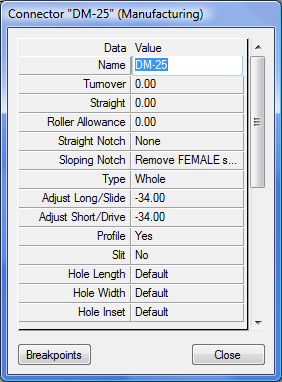

To amend any of these details, double-click on the relevant connector name (or right-click and choose Edit), to create a new connector click on the

icon ensuring you are within the relevant library. In either case, a dialog similar to the following displays.

icon ensuring you are within the relevant library. In either case, a dialog similar to the following displays.

Library: Choose from the list which table is to be reviewed or edited.

Rectangular Connector Table: The following can be defined for each connector.

Name: Enter a name that describes the connector. Try to keep the name as short as possible since some dialogs only display a limited number of characters.

Turnover: This value defines the extra metal allowance required to form the connector. This value will always be added to the duct.

Roller Allowance: This is the values used when the part is Oversized and has to be sliced, this will cut back the allowance on the Oversized Seam so that the seam rollers wont seam over the Connector Allowance. This is used in conjunction with the settings in the Oversized Seam.

Straight Notch: This is the notch used to remove connector / seam intersections.

Sloping Notch: This is the notch used in situations such as transitions and drop cheeks. Its primary usage is to remove taper extensions.

Type: The drop-down menu lists the different types of connector setting, details of which are listed below.

- Whole : One connector per duct end.

- Shared : One connector for every two duct ends assigned.

- S & D Auto : The "C" drive cleat will automatically be assigned to the longest of the two sides, either the width or depth. This type is shared.

- D & S Auto : The "S" cleat will automatically be assigned to the longest of the two sides, either width or depth. This type is shared.

- S & D Manual : The "C" drive cleat will always be assigned to the width. This type is shared.

- D & S Manual : The "S" cleat will always be assigned to the width. This type is shared.

Adjust Long / Slide / Adjust Short / Drive : These values are added or subtracted from the length of the connectors flange material, when lengths are shown on reports.

Profile : This determines whether the connector is an external (Yes) or self flange (No).

Slit: The options here are as follows:

- No: Nothing will be applied

- Slit: The slits are used primarily for setting up connectors such as TDC or CGF and the main settings are defined in the Pattern Options section of the Database, more information on which can be found Pattern Options. There are also Connector Dependant Settings that can be set on each connector.

- Hole: Selecting Hole will use the Hole Length option to determine the Diameter of the Hole in the connector.

- Slotted Hole: Selecting Slotted Hole will use the Hole Length and Hole Width options to determine the size of the Slotted Hole.

Hole Length : This is used to determine the Diameter of a Hole if a Hole is applied in the Slit option. The user can enter a value or set it to Default which will pick up the values contained in the Pattern Options section of the Database.

Hole Width: This is used to determine the Width of a Slotted Hole if a Slotted Hole is applied in the Slit option. The user can enter a value or set it to Default which will pick up the values contained in the Pattern Options section of the Database.

Hole Inset: This field will determine how far from the connector edge the hole/slits is displayed . The user can enter a value or set it to Default which will pick up the values contained in the Pattern Options section of the Database.

Centers: This field will determine the Maximum distance between centers of the holes. The software will determine the best symetrical number of holes, up to the value entered, so that you do not get holes too close or far apart in the center of the part. The user can enter a value or set it to Default which will pick up the values contained in the Pattern Options section of the Database.

Outer: This field will give the place the first hole the entered value from the seam edge. Negative values can be entered if creating "Ear" type connectors. The user can enter a value or set it to Default which will pick up the values contained in the Pattern Options section of the Database.

Fold Slit: This can be set to Yes or No and specifies whether or not fold slits are included in the development.

Fold Slit Gap: The distance from the top of the connector that the slit will start. A value of 0.0 will cut the slit from the top edge.

Fold Slit Body Gap: The distance from the Straight allowance that the slit will terminate. A value of 0.0 will cut the slit the full Turnover allowance.

Override Tie Rod Offset Width: There are 3 settings that can be used. " Not Used" will ignore this setting and offset the Tie Rod according to the Tie Rod settings in Stiffeners. " Off" will override the settings in the Tie Rod settings and remove any tie rods from the connector end. " Value" will allow you to override the offset in the Tie Rod Settings and apply the new value when this connector is used.

Override Tie Rod Offset Depth : These setting are the same as the Override Tie Rod Offset Width with the exception that they are applied to the items Depth.

Override Insulation Adjust: There are 2 settings that can be used. " Not Used" Will ignore this setting and apply the insulation adjustment determined in the Pattern Options - Insulation section of the Database " Value" will allow you to override the settings applied in the insulation adjustment determined in the Pattern Options - Insulation section of the Database.

Seam Cut Back (Male) : A value here will cut remove the seam from the Male side, using the specified value from the connector end, this will be in addition to any seam removal applied in the Connector notching.

Seam Cut Back (Female) : A value here will cut remove the seam from the Female side, using the specified value from the connector end, this will be in addition to any seam removal applied in the Connector notching.

Bevel Cut End: This has been added to let ductboard users, who use a Router or Angled Knife, to Bevel the end where the connector would be applied, i.e. to allow for a Cap End to fit inside. The options are Yes or No.

Fixing Spacing : This allows for the spacing of fixing holes on the Connector. If set to Default it will pick up the values entered into the Fixing Holes options in the Pattern Options section of the Database. A Value entered here will set the spacing between hole centers.

Fold Notch Angle : When a connector Fold Notch is applied to the fitting this will set the default angle for the Notch.

Breakpoints: Breakpoints for connectors in the Fabrication products are there for the 3D Viewer functionality and jobs created which are brought into the Fabrication products for manufacture. The Breakpoints allow the user to control how the connector is displayed in the drawing and can also control its node points. For more information on Breakpoints click Connector Breakpoints.

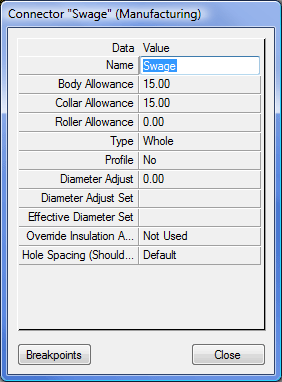

Round and Oval Connector Table

Round and Oval connectors have different fields defined.

Name: Enter a name that describes the connector. Try to keep the name as short as possible since some dialogs only display a limited number of characters.

Body Allowance: The allowance added to the body of the development.

Collar Allowance: The allowance added to the collar.

Roller Allowance: For oversized developments, the extra allowance on the connector to account for additional roller notching.

Type: This can be Whole (one connector per duct end) or Shared (if the connector is shared between the end pieces, and so will be one connector per every two duct ends assigned) - used primarily for producing the correct data on reports.

Profile: This will be either Yes or No, and determines whether the connector is an external (Yes) or self flange (No) for printing purposes.

Diameter Adjust: This allows the diameter of round and oval ends to be increased or decreased depending on the connector being used on the end. This adjustment is applied in addition to any other existing adjustments. For more details, see the topic Diameter Adjusts.

Diameter Adjust Set: A predefined set of parameters that are created in the can be applied to the connector using this field. These parameters are created in the Material Database and are applied to the item when the Material Specific is applied in the Diameter Adjust field.

Effective Diameter Set: This will apply predefined adjustments, to the item, that were created in the Effective Diameters table when the Use Connector Dependant Effective Diameters check box is applied.

Override Insulation Adjust: There are 2 settings that can be used. " Not Used" Will ignore this setting and apply the insulation adjustment determined in the Pattern Options - Insulation section of the Database. " Value" will allow you to override the settings applied in the insulation adjustment determined in the Pattern Options -Insulation section of the Database.

Hole Spacing Shoulder: This uses the Value entered here as the spacing of holes from the Shoulder of the fitting, if set to Default it will use the values entered in the Pattern Options - Fixing Holes Database.

Breakpoints: Breakpoints for connectors in the Fabrication products are there for the 3D viewer functionality and allow the user to control how the connector is displayed in the drawing or viewer node points are also set within the Breakpoints.