Machine kinematics

For CNC machines, a machine definition includes information about its kinematics, which describes how the physical CNC machine moves when running NC code. Understanding kinematics is important for ensuring accurate simulations and generating reliable NC code.

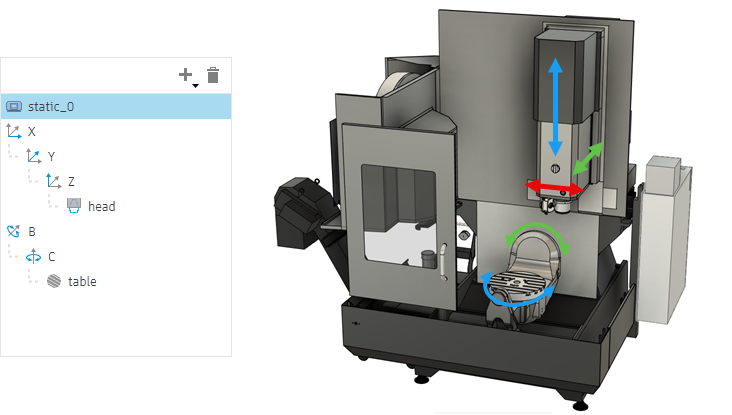

The kinematics tree

A kinematics tree provides a hierarchical view of the machine’s components and their relationships. The specific items and their order in the kinematics tree vary depending on the CNC machine type.

Items that can be found in a kinematics tree:

- Linear Axis: Represents an axis of motion that moves in a straight line, such as the X, Y, or Z axes.

- Rotary Axis: Represents an axis of motion that rotates around a fixed point, such as the A, B, or C axes.

- Static: Represents stationary elements of the machine, such as its base or frame.

- Head: Holds the cutting tool on a milling or mill-turn machine.

- Turret: Holds multiple cutting tools on a lathe or turn-mill machine, allowing for quick tool changes.

- Table: Holds the workpiece on a milling or mill-turn machine.

- Main Spindle: Holds and rotates the workpiece during turning operations on a lathe or turn-mill machine.

- Sub Spindle: Serves as a secondary spindle on a lathe or turn-mill machine, enabling simultaneous machining on both ends of the workpiece.

Different CNC machine types

Milling machines typically have a head and a table. The head is equipped with a spindle that holds and rotates a cutting tool used for milling operations, and the table holds the workpiece.

Lathes typically have a turret to hold stationary tools used for turning operations, and a main spindle, and possibly a sub spindle, to hold and rotate the workpiece.

Turn-mill machines are lathes but with the capability of performing milling operations. They typically have a turret to hold stationary tools used for turning operations, and a main spindle, and possibly a sub spindle, to hold and rotate the workpiece. In turn-mill machines, the turret can be equipped with live tooling, allowing it to hold a rotating cutting tool used for milling operations.

Mill-turn machines are milling machines but with the capability of performing turning operations. Similar to milling machines, mill-turn machines typically have a head and a table. However, the head can hold a stationary tool used for turning operations, and the table can rotate to hold and spin the workpiece.

Examples of kinematics tree hierarchies

To help illustrate the concept of machine kinematics, below are some examples of kinematics tree hierarchies for different types of CNC machine:

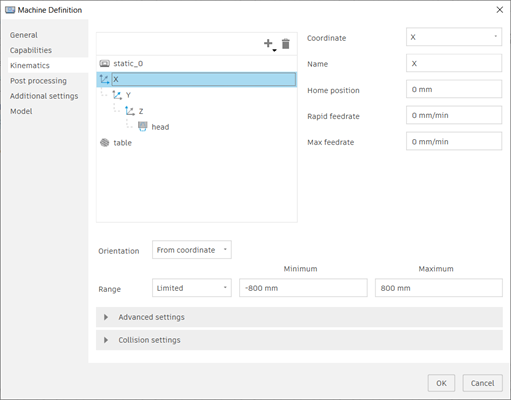

3-axis milling machine

In this example:

- The X, Y, and Z axes control the position of the machining head that holds the cutting tool.

- The stock is stationary on the table.

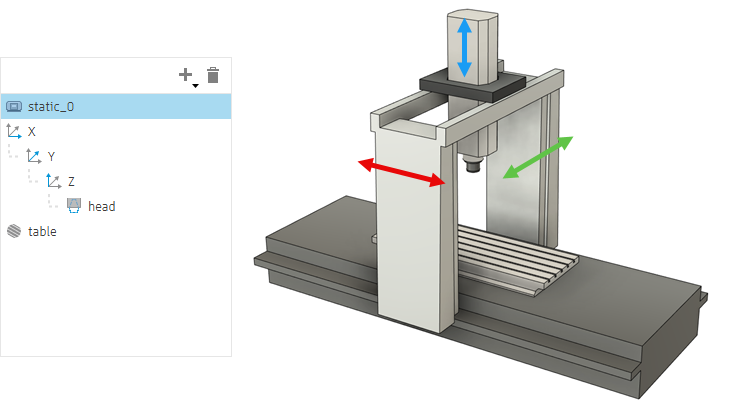

5-axis head-head milling machine

In this example:

- The Z, C, and B axes control the position and rotation of the machining head that holds the cutting tool.

- The Y and X axes control the position of the stock on the table.

Because all rotations are completed by the machining head, the machine's configuration is known as head-head.

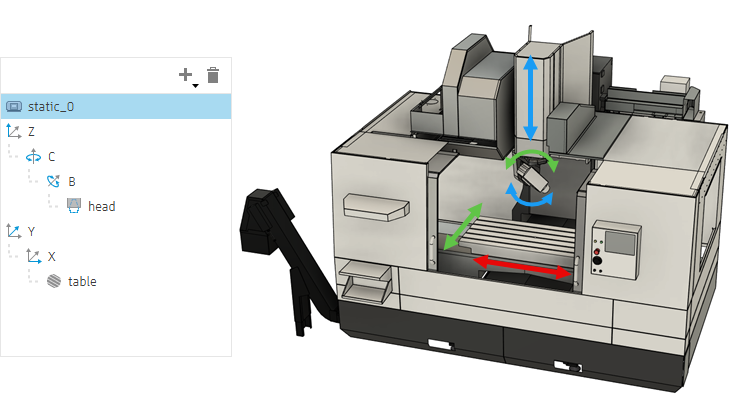

5-axis table-table milling machine

In this example:

- The X, Y, and Z axes control the position of the machining head that holds the cutting tool.

- The B and C axes control the rotation of the stock on the table.

Because all rotations are completed by the table, the machine's configuration is known as a table-table.

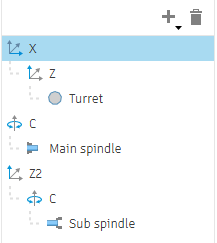

Multi-axis turn-mill machine (dual-spindle lathe with live tooling)

In this example:

- The X and Z axes control the tool’s position along the stock, while the turret holds the tools for machining.

- The C axis controls the rotation of the stock held by the main spindle.

- The Z2 and C axes control the rotation of the sub spindle, allowing for operations on the opposite end of the stock.

Collision checking

You can choose which pairs of items of a machine are included or excluded from collision checks when simulating with a machine model. Collision checking against many items can slow the verification process during simulation. If you exclude pairs of items from the checks, collisions with those pairs are not reported.