Workflow: Using and creating machine definitions

Use and create machine definitions in Fusion, ensuring precise simulation and NC code generation for your specific CNC machine or additive printer. Use an existing machine definition or create and use a custom machine definition.

Using existing machine definitions

Using existing machine definitions in Fusion can save you time and effort. There are two options available for using an existing machine definition:

Select a preconfigured machine definition: Fusion provides a range of preconfigured machine definitions in the Fusion Library folder, covering commonly used machines. By selecting a machine definition that matches your specific CNC machine or additive printer, you can quickly set up your operations with minimal adjustments required. You need only verify that the machine definition settings align with your machine's specifications.

Using custom machine definitions: Your company or organization may have already created custom machine definitions that accurately represent your specific machines. By using these custom machine definitions, you can ensure precise simulation and NC code generation tailored to your CNC machine or additive printer.

Use an existing machine definition

Create a setup and select an existing machine definition that matches the machine you will be using. If applicable, ensure that the machine definition includes a linked post processor and a linked machine model.

Create operations to manufacture your part.

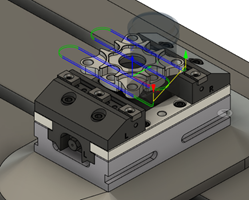

Simulate with the machine or simulate without the machine to visualize the machining process and identify any potential issues.

Generate the necessary output file for your CNC machine or additive printer.

Creating custom machine definitions

Creating a custom machine definition is necessary when there is no existing machine definition that matches your specific CNC machine or additive printer. When creating a custom machine definition, the process differs based on whether you are working with a CNC machine or an additive printer.

Create and use a custom machine definition for a CNC machine

If working with a CNC milling machine, download or create a machine model that accurately represents the physical CNC milling machine. You can often obtain machine models on the website of your CNC machine manufacturer.

Create a machine definition that accurately represents your CNC machine or additive printer:

- Set the machine capabilities to reflect its specific functionalities.

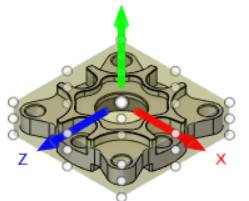

- Define the machine’s kinematics.

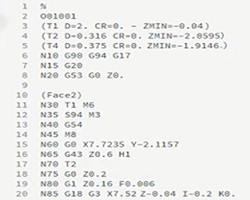

- Link the machine definition to a suitable post processor. The post processor converts the generated operations into machine-specific instructions.

- Configure the multi-axis options according to your CNC machine’s capabilities.

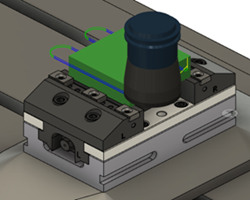

- If working with a CNC milling machine, link the machine definition to the machine model you obtained or created. This ensures that the simulated machining operations accurately represent the movements and constraints of your CNC milling machine.

Create a setup and select the machine definition that you created.

Create operations to manufacture your part.

Simulate with the machine or simulate without the machine to visualize the machining process and identify any potential issues.

Generate the necessary output file for your CNC machine. The post processor converts the operations into instructions that your machine understands, ensuring compatibility.

Create and use a custom machine definition for an additive FFF (fused filament fabrication) printer

Create a machine definition that accurately represents your additive printer:

- Specify the machine's vendor and model, its platform dimensions and settings, the machine's limits and information about its extruders.

- Link the machine definition to a suitable post processor. The post processor converts the generated operations into machine-specific instructions.

Create a setup and select the machine definition that you created.

Create additive operations to manufacture your part.

Simulate the additive operations to visualize the additive manufacturing process and identify any potential issues.

Generate the necessary output file for your additive printer.