The Machine Builder

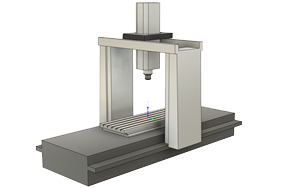

The Machine Builder enables you to view and configure the machine model for a CNC machine. With the Machine Builder, you can modify an existing machine model to accurately represent the CNC machine’s physical components, movements, and behaviors during machine simulation. This enables you to gain insights into how your physical CNC machine will move and operate when running NC code.

To use the Machine Builder, the machine model must be linked to a machine definition.

Adjusting axis directions

The Machine Builder provides the flexibility to adjust the axis directions of your machine model. This allows you to align the axes of the machine model with the coordinate system, ensuring accurate representation and simulation. By editing the axis directions, you can achieve precise and realistic movements in the simulation.

Assigning components

In the Machine Builder, you can assign components and define attachment points to ensure that the machine model accurately represents the physical configuration of your CNC machine.

Assigning components involves identifying the elements of the machine that represent the linear axes, rotary axes, and static elements such as the base or outer casing. Defining attachment points involves determining where the tool attaches to the spindle and where the part sits on the table.

Verifying movements by jogging axes

To validate the accuracy of the machine model, the Machine Builder enables you to verify movements by jogging axes. This interactive process enables you to visually inspect and validate the behavior of the machine model. By jogging the axes, you can ensure that the movements align with the expected behavior of your physical CNC machine.