To view and manage the probe database and display the calibration details for a CMM, click Tools tab > Machine panel > Probes. The details of the probe being used and its current calibrations are displayed in the Machine Configuration dialog .

The information shown in the Machine Configuration dialog, and the way in which you work with the database, depends on the communication protocol you selected and the type of measuring device being used:

Manage a CNC/DCC-controlled CMM using the device or I++ ClientTool protocol

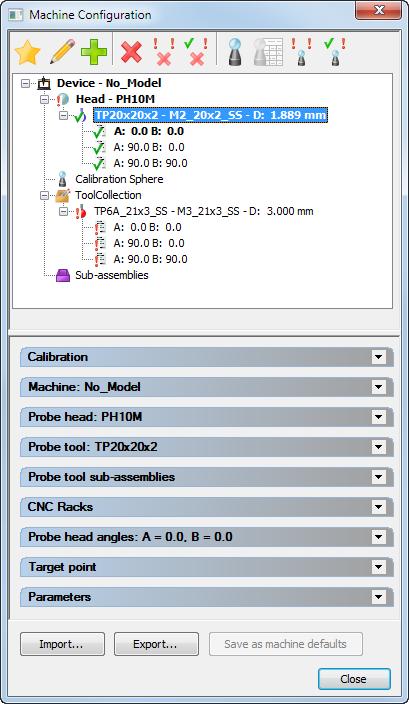

The Machine Configuration dialog displays the configuration and calibration details of the measuring device that PowerInspect is currently configured for. For example:

Use the toolbar and the expandable areas of the dialog to:

- Activate and manage probe tools

- Specify the calibration sphere

- Select a probe head

- Define and maintain probe tools

- Define and maintain sub-assemblies

- Specify racks

- Specify probe head angles

- Specify a target point

- View and change the CMM parameters

- Import and export settings

Manage a manual CMM using the device or I++ ClientTool protocol

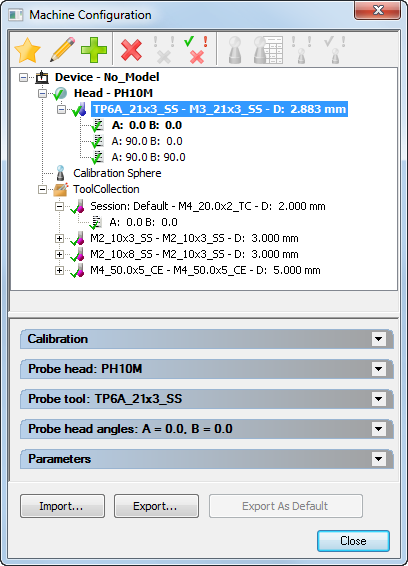

The Machine Configuration dialog displays the configuration and calibration details of the measuring device that PowerInspect is currently configured for. For example

Use the toolbar and the expandable areas of the dialog to:

- Activate and manage probe tools

- Specify the calibration sphere

- Select a probe head

- Define and maintain probe tools

- Specify probe head angles

- Import and export settings

Manage a CMM using the I++ probe database

When PowerInspect is not connected to the measuring device, the dialog does not display any information because the details of the measuring device are stored in the I++ Server.

When

PowerInspect is connected to the measuring device, the dialog displays the details specified in the I++ Server, and indicates the calibration status of the probe positions by displaying a

(calibrated) or

(calibrated) or

(uncalibrated) marker for each item in the list.

(uncalibrated) marker for each item in the list.