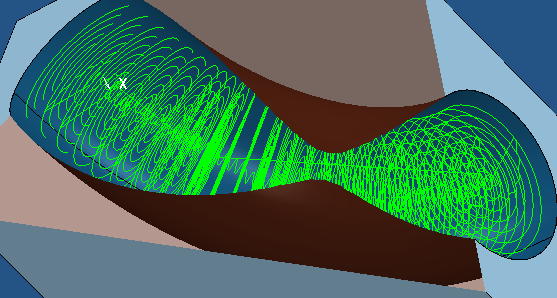

Use the Port Area Clearance strategy for volume removal of material inside a port.

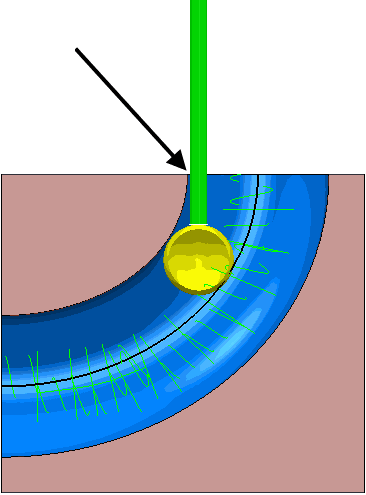

PowerMill starts machining the port with a 3-Axis strategy if it can:

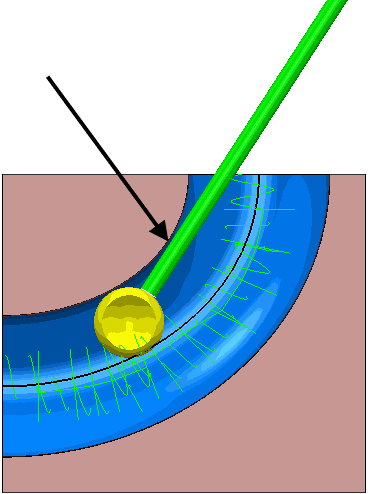

When the toolpath can no longer be created without a collision, PowerMill automatically creates a tool axis which enables further 3+2 Axis machining. This continues down the port and PowerMill then create a 5-Axis strategy if necessary:

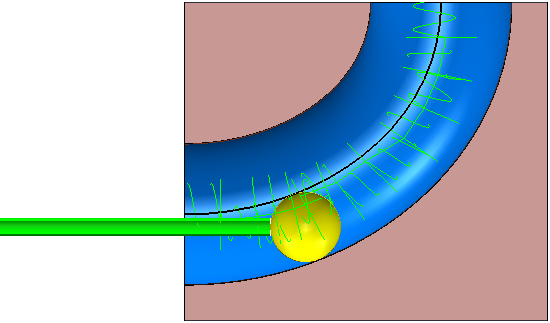

When no further toolpath can be created while accessing one side of the port, PowerMill accesses the port from the other end and applies the same principle of machining with 3+2 Axis strategies wherever possible.

The pages associated with the Port Area Clearance strategy are:

- Port — The main page used to define the area clearance of the port.

- Workplane limits — Settings to determine which portion of the model is machined and controls the direction of the slices.

- Ramping — Settings to determine how the tool descends into the block.

- Order — Settings to determine which ends of the ports are used and how far they are machined in each end of the port.

The remaining pages are common toolpath strategy pages.