When creating hole groups in PartMaker, you can extract data from a selected hole on a solid model for use in the Hole Group Parameters dialog:

Hole Group Parameters dialog — Milling

Hole Group Parameters dialog — Turning

To extract the data:

- Select the Extract Parameters from Solid option on the Hole Parameters dialog.

- On the solid model, select the portion of the hole that is the Major Diameter of the hole.

- Click Extract on the Hole Parameters dialog to extract the data.

Definitions

Recognized Hole — Several surfaces grouped together by PartMaker to make a hole on the solid. As well as recognizing a hole, PartMaker includes all cylinders that make at least a half circle.

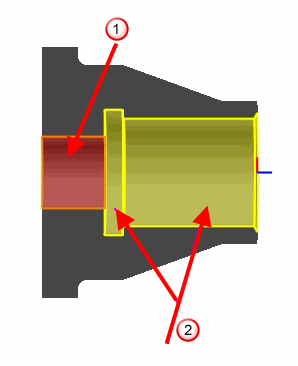

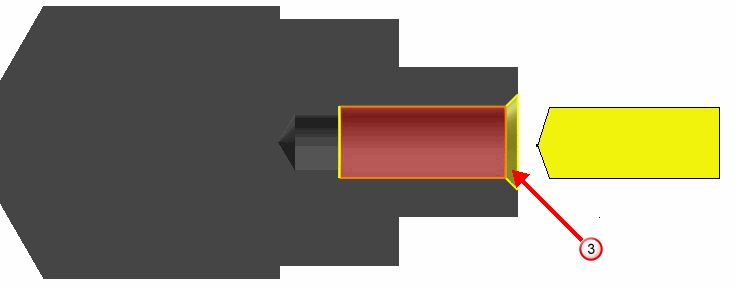

Selected Wall Surface

— This is the surface you have selected (see

) on the solid model to be the Major Diameter of the hole.

) on the solid model to be the Major Diameter of the hole.

Marked Surfaces

—

PartMaker uses these surfaces (see

) to calculate the

Depth and

Surf values for the hole.

) to calculate the

Depth and

Surf values for the hole.

Data extracted from holes

PartMaker extracts the following data for hole groups:

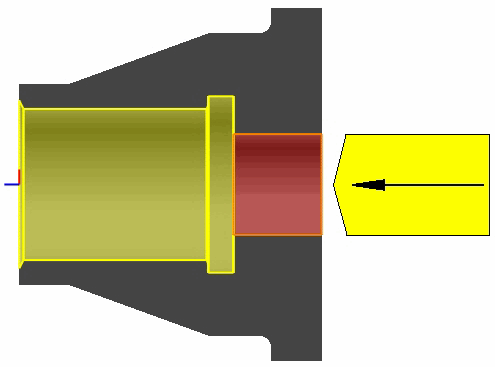

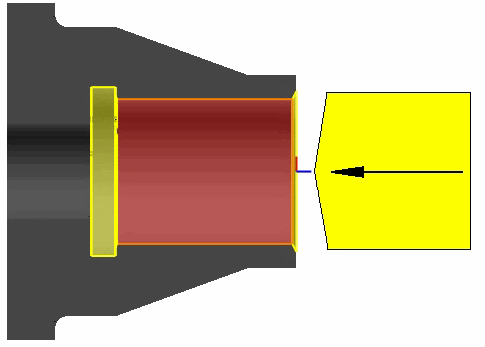

Through Hole — If, further down from the Major Diameter you selected, there is a diameter that is smaller than the Major Diameter, PartMaker does not classify the hole as a through hole. For example:

- Through hole example:

A through hole is created because there is no diameter further down the hole that is smaller than the Major Diameter.

- Blind hole example:

A blind hole is created because there is a diameter that is smaller than the Major Diameter. The hole stops above the hole section where the diameter becomes smaller.

Diameter — This is the larger diameter of the wall surface you selected.

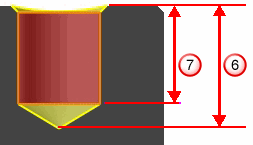

Chamfer

— If the surface directly above the selected wall of the hole is a cone that reduces in diameter,

PartMaker calculates this chamfer (see

) for the hole group. If there is no cone, or it is not directly above the selected surface,

PartMaker sets the chamfer value to zero.

) for the hole group. If there is no cone, or it is not directly above the selected surface,

PartMaker sets the chamfer value to zero.

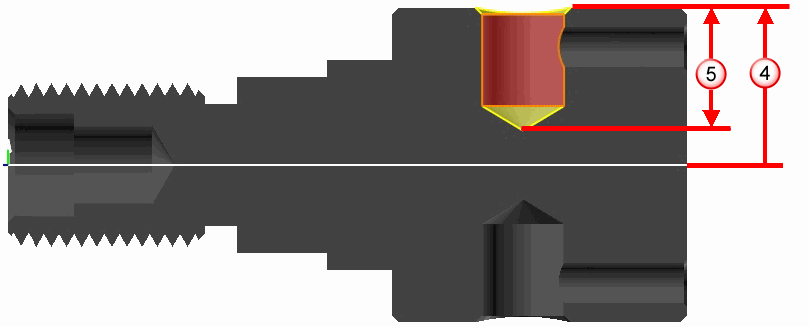

Surf

—

PartMaker finds the top of all of the selected surfaces, relative to the Face Origin, and uses this as the

Surf value (see

).

).

Depth

—

PartMaker finds the depth of all of the selected surfaces, relative to the top of the hole, and uses this as the

Depth

value (see

).

).

To — If PartMaker recognizes the hole as a blind hole, it uses one of the following settings:

- Shoulder of Major Tool

— Used when the bottom hole surface is a cone. The hole depth is adjusted to the top of the cone (see

).

).

- Bottom of Major Tool

— Used when the bottom hole surface is a flat plane. The hole depth is not adjusted.