Turning Profile Roughing strategy

The Turning Profile Roughing strategy removes the maximum amount of stock as quickly as possible to achieve a shape close to the desired part geometry.

Roughed parts have poor surface finish and are inaccurate in terms of dimensions. However, thanks to roughing, the following machining operations are more efficient.

Turning Mode and Cycle

The strategy removes stock from the outside diameter, called Outside Profiling, or from the inside diameter, called Inside Profiling, of the part depending on the selected Turning Mode.

Turning Profile Roughing removing material from the Outside Diameter using different tool orientations.

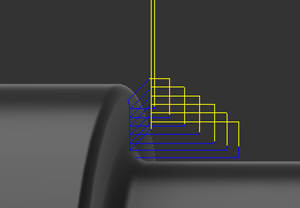

The Mode with the Cycle option on the Passes tab determine the cutting direction of the tool. You can choose a cycle with:

- Vertical passes - The tool cuts from the front toward the back of the stock.

- Horizontal passes - The tool cuts from the outside toward the centerline for Outside Profiling. For Inside Profiling, The tool cuts from the centerline toward the outside.

- Back cutting - The tool cuts from the back to the front of the stock.

Groove suppression

To reduce stress on the tool and the part, on the Geometry tab, you can suppress machining grooves in the toolpath. Depending on selected groove faces, Groove Suppression excludes the groove from machining or machines a shallower groove. Large cutting forces may lead to damaging a tool and poor surface finish. By machining a shallower groove, you reduce cutting forces by distributing them on a larger area.

Grooving - machining grooves

To prevent the tool from entering all grooves in the part, from the Grooving drop-down on the Passes tab, select one of the following options:

- Axial undercuts

- Radial undercuts

- Axial and radial undercuts.

You can also prevent undercut machining. Efficiency of undercut machining depends on the tool geometry.

Depth of a cut

The Turning Profile Roughing strategy lets you to generate a toolpath with equal depths of cuts. To achieve it, select Even Depths of Cut on the Passes tab.

You can also control the maximum amount of stock to remove at each cut by specifying a value of the Maximum Depth of Cut on the Passes tab. The higher the value, the faster stock removal. The amount of tool stress increases as the speed of stock removal grows.

For more information, watch the Turning profile roughing video.

Skip wall passes

You can reduce the number of tool movements to save time in the roughing toolpath. On the Passes tab, check Skip Wall Pass to skip the cusp cleanup move after every cutting move. After the roughing toolpath, follow up with a finishing toolpath to achieve the desired surface finish.

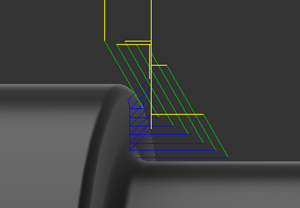

Angled entry moves

To enhance tool life, you can enter the part at an angle to ramp into the stock area instead of plunging directly into it. The direction of the entry move is measured counterclockwise from the setup Z-axis. All angled entry leads are checked for gouges against the model. You can set the start of the lead-in move by specifying the clearance, which is an incremental distance away from the stock, and then set a feed rate.

|

|

| Plunge into stock | Angled entry ramping into stock |