Use the Flat machining page to define how flat areas are machined.

Machine flats — Select how to identify flat areas on the model. These options determine the location of the machining level heights.

- Off — When selected, flat areas are not considered. Selecting this option disables all other settings on this page.

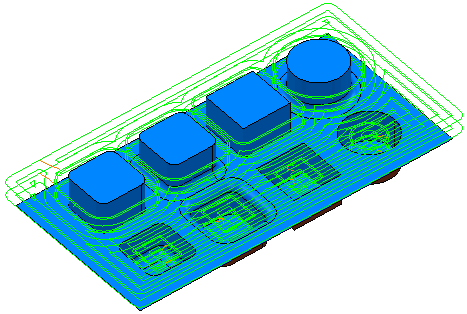

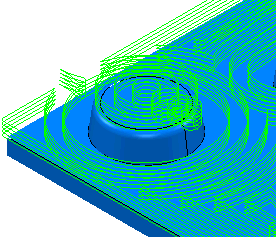

- Area — Select to machine flat areas only (rather than the whole level).

Looking from a different angle, you can see that only the flat areas are machined in the first level:

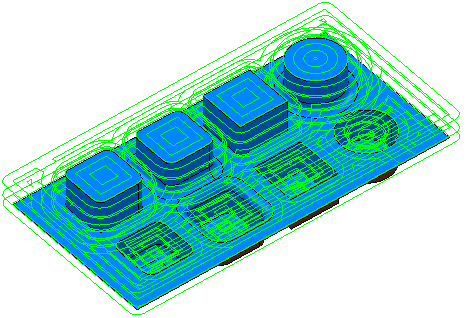

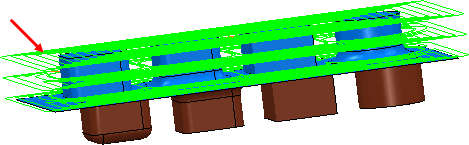

- Level — Select to machine whole flat levels. Only the Multiple cuts and Flat tolerance options are available when you select Level.

Looking from a different angle, you can see that three complete levels are machined:

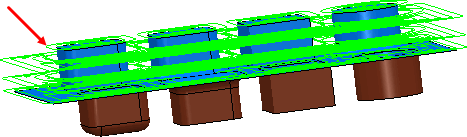

Multiple cuts — Select to enable additional settings for specifying multiple cuts.

Number of cuts — Enter the number of passes.

Stepdown — Enter the distance between each pass.

Add a final stepdown — Select to enable a different distance for the final pass. For example, you may want a general stepdown of 3 mm with a final pass that has a 1 mm stepdown. This gives you a couple of roughing passes followed by a finishing pass.

Final stepdown distance — Enter the distance of this final pass from the penultimate pass. For example, you may want a general stepdown of 3 mm with a final pass that has a 1 mm stepdown. This gives you a couple of roughing passes followed by a finishing pass.

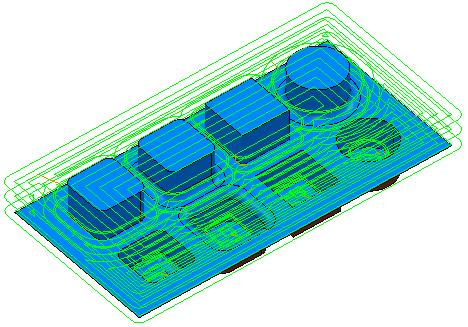

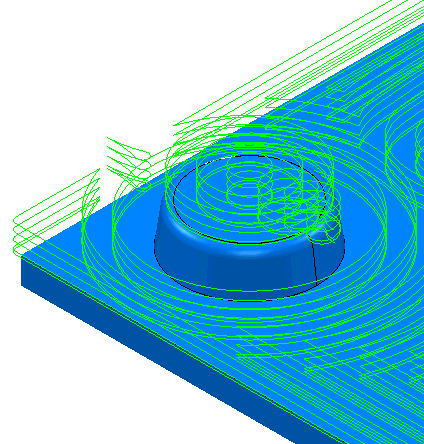

Allow tool outside flat — Select this option to allow the tool to go outside the flat area. This alleviates the problem of running the tool along a sharp edge.

Approach allowance (tool diameter units) — Enter the approach outside as a percentage of the tool diameter.

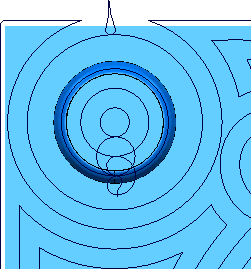

Flat tolerance — Enter a tolerance to find areas that are almost flat (that is, flat within the tolerance specified here).