Use the Offset page to specify settings for an offset-style area clearance strategy, which creates cutting moves by offsetting the model or block.

Advanced offset settings

Maintain cut direction — Select this option to maintain the cut direction specified in Cut direction - Area. Deselect this option to allow PartMaker to create a toolpath with fewer tool lifts. PartMaker adheres to the cut direction as far as possible, but priority is given to fewer tool lifts.

Spiral — Select this option to enable spiralling to occur (where the original offsets are closed and have one-to-one nesting).

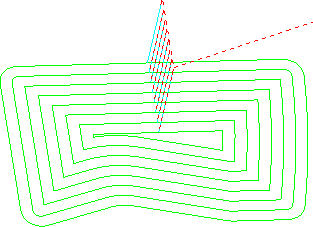

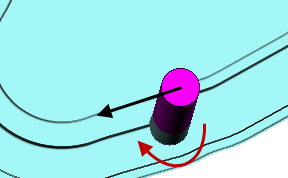

For example, it converts this:

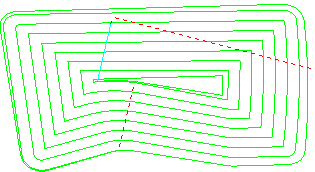

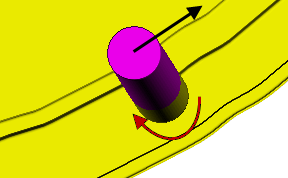

to this:

Remove cusps — Use this option to control both the maximum stepover and the addition of cusp removal moves. This option is selected by default, which means that the stepover is limited to the maximum flat diameter of the tool (so, a 10 mm tool with a 2 mm tip radius has a maximum stepover of 6 mm). PartMaker adds cusp-reduction moves to ensure that no cusps are left and that no tall, thin upstands are formed.

When the option is deselected, the stepover is limited to the diameter of the tool and cusp reduction moves are added only to prevent tall, thin upstands forming. This can be useful when machining soft materials where any remaining cusps will be removed by the next machining level height, as the additional moves slow down machining unnecessarily. However, additional moves to prevent the forming of tall, thin upstands are added.

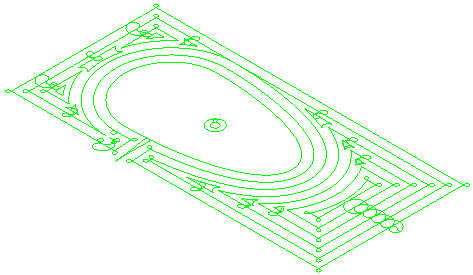

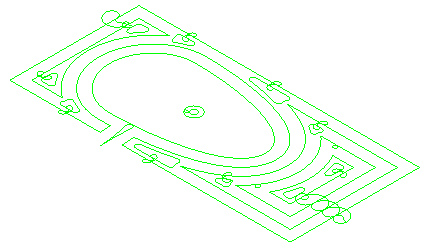

These two toolpaths were created using the same tool (a tip-radiused tool with a 10 mm radius and a 2 mm tip radius), and at the same setting (a stepover of 8 mm) on the Model area clearance page.

With Remove cusps selected:

With Remove cusps deselected:

Machine smallest first — Select this option to machine the smallest islands of material first to avoid tool damage.

Cut direction — Select a milling style for Profile and Area.

- Climb — Select to create toolpaths using only climb milling, where possible. The tool is on the left of the machined edge when viewed in the direction of tool travel.

- Conventional — Select to create toolpaths using only conventional or upcut milling, where possible. The tool is on the right of the machined edge when viewed in the direction of tool travel.

- Any — Select to create toolpaths using both conventional and climb milling, as appropriate. This minimizes the tool lifts and tool travel.

Direction — Select an option to control the direction of offset moves.

- Auto — Select this option to specify that PartMaker automatically selects the Direction based on whether a core or a cavity is being machined. A core is defined as an area whose outermost boundaries are ALL lying on the outside of the block.

- Inside out —Select to machine from the innermost profile, moving outward.

- Outside in — Select to machine from the outermost profile, moving inward.