Use the Wall finishing page to specify a Final stepover that is different from the Stepover specified on the Model area clearance page:

Wall finishing — Select this option to specify a Final stepover that is different from the normal stepover.

Final stepover — Enter a distance for the final profile pass. For example, you may want a general stepover of 3 mm with a final pass that has a 1 mm stepover. This gives you a couple of roughing passes followed by a finishing pass.

Last pass only — Select this option to specify that PartMaker performs the final profile pass only on the final Z height and not the preceding Z heights.

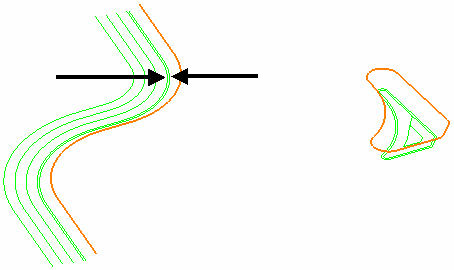

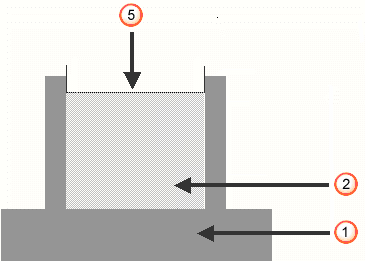

Last pass only creates an area clearance move with an allowance of the Final stepover for every machining level until the lowest level. At the lowest level, it is followed by a final profiling pass without the allowance at the lowest machining level height.

One final profile pass at the lower machining level only.

One final profile pass at the lower machining level only.

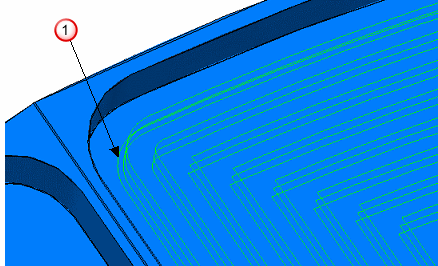

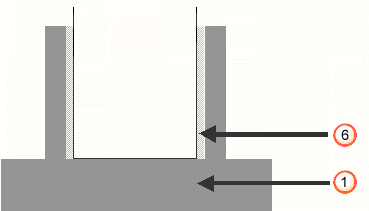

The first area clearance move clears the following:

Finished part

Finished part

Material to be removed

Material to be removed

Profile allowance

Profile allowance

First area clearance move

First area clearance move

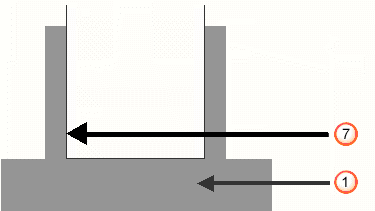

Followed by a second area clearance move:

Second area clearance move

Second area clearance move

And so on down the part:

Final level area clearance move

Final level area clearance move

This is then followed by a single profile move:

Profile move

Profile move

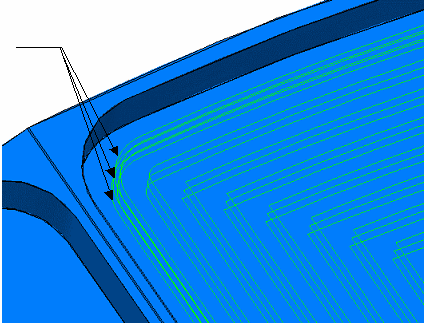

This technique can be used to finish the part with one final profiling pass where you cut on the side of the tool, though a finishing pass may be required.

When deselected, each Z height has a final profile pass.

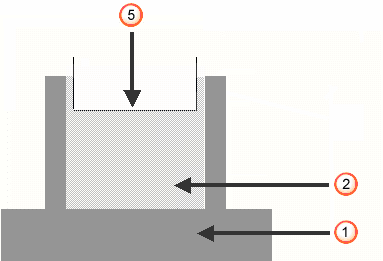

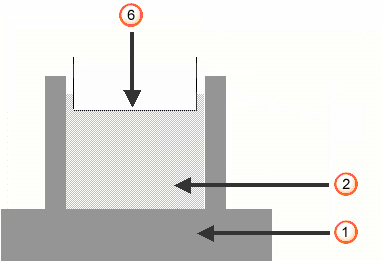

Final Profile Pass - Every Z creates an area clearance move with an Allowance, followed by a final profiling pass without the allowance, at the same Z Height.

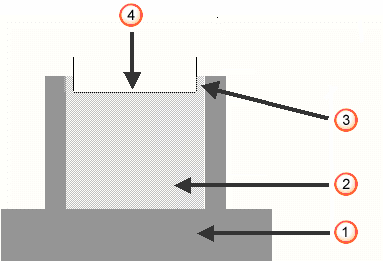

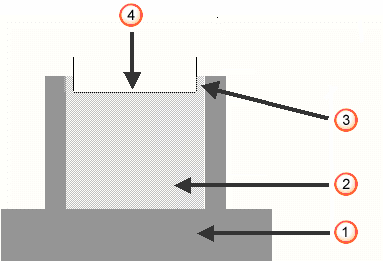

The first area clearance move clears the following:

Finished part

Finished part

Material to be removed

Material to be removed

Profile allowance

Profile allowance

First area clearance move

First area clearance move

Followed by a profile move:

First profile move

First profile move

Then a second area clearance move:

Second area clearance move

Second area clearance move

And so on down the part.

This is useful for machining thin, high walled parts (typically aluminium parts with ribs or extruded parts with thin walls). You area clear one level and then profile that level. This minimises the vibration of walls and maintains the rigidity of the part as you machine it.

This technique can be used to finish the part as it descends down the part, although a final finishing pass may be required.