Turning Trace strategy

The Turning Trace strategy creates a toolpath that follows a model contour or sketch to machine complex geometry, such as undercut grooves.

Gouge checking occurs for the tip of the tool but not the rest of the insert or the holder geometry.

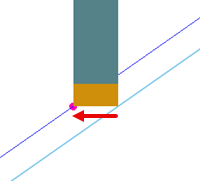

Sideways compensation

Use the Sideways Compensation parameter to determine which side of the selected contour to machine.

Return on curve

Instead of retracting to the clearance plane, the tool can return back on the same contour it machined for a safer retract move or it can also act as a finishing pass to remove any material that was left behind because of tool deflection.

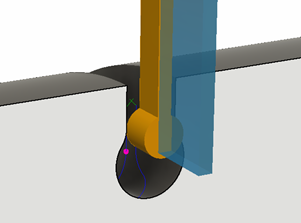

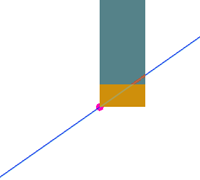

Compensate for tool width

When using a grooving tool, you can cut with the back edge of the insert instead of the leading edge by shifting the toolpath by the tool width. The back edge of the insert is then gouge checked against the model. Generally, you can use this option when the sketch you are using to drive the toolpath represents the profile of the part you are machining. If the sketch is the actual path you want the leading edge of the tool to follow, then you do not need to compensate for the tool width.

|

|

| Selected | Deselected |

| Cutting with back edge of insert (left side) | Cutting with leading edge of insert (right side) |