Use the 3D offset finishing page to specify settings for creating a series of offsets starting at the outer boundary and offsetting towards the center. The shape of the offset is defined by pattern curves. To specify the profile curves you want to use as pattern curves, double-click on a profile in the CAM Face window to display the Curve Properties dialog.

Spiral — Select to create a spiral 3D offset toolpath.

This minimizes the number of lifts of the tool and maximizes cutting time while maintaining more constant load conditions and deflections on the tool.

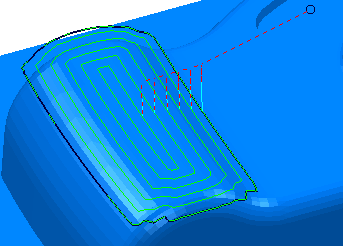

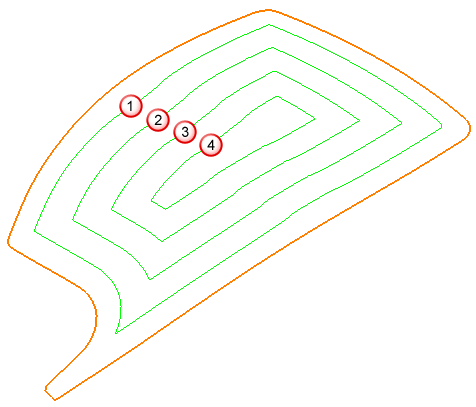

- With Spiral deselected:

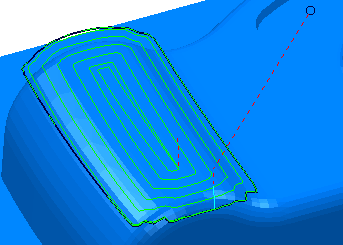

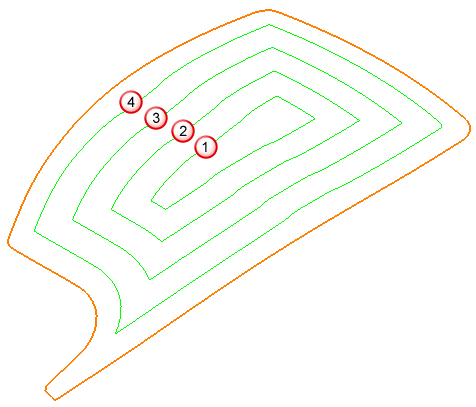

- With Spiral selected. This minimizes the number of tool retracts and converts the original closed contours into one long spiral.

Smoothing — Select to smooth offsets of toolpath segments over the model.

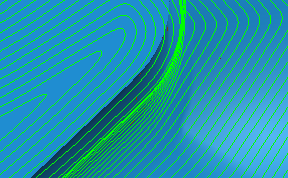

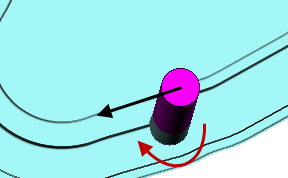

- With Smoothing selected:

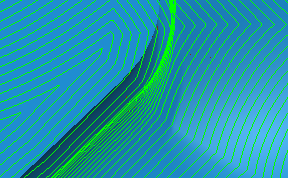

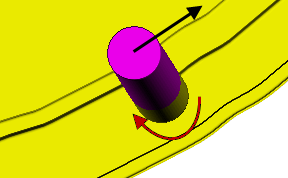

- With Smoothing deselected:

Reverse toolpath segment order — By default, toolpath segments are ordered out-to-in:

Select this option to reverse the order of toolpaths segments so they are in-to-out.

Tolerance — Enter a value to determine how accurately the toolpath follows the contours of the model.

Cut direction — Select the milling technology.

- Climb — Select to create toolpaths using only climb milling, where possible. The tool is on the left of the machined edge when viewed in the direction of tool travel.

- Conventional — Select to create toolpaths using only conventional or upcut milling, where possible. The tool is on the right of the machined edge when viewed in the direction of tool travel.

- Any — Select to create toolpaths using both conventional and climb milling, as appropriate. This minimizes the tool lifts and tool travel.

Thickness — Enter the amount of material to be left on the stock within tolerance. Thickness is applied as an offset to the tool in all directions:

Stepover — Enter the distance between successive machining passes.