Use the Raster finishing page to specify settings for a raster finishing strategy, which creates a toolpath by taking a pattern of curves, within a boundary, and projecting points from these curves onto the model.

Raster toolpaths are often used on open parts and are best-suited to rectangular models. This is a robust machining strategy that works well on many models except for areas that are vertical (or near-vertical).

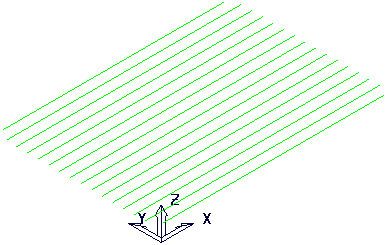

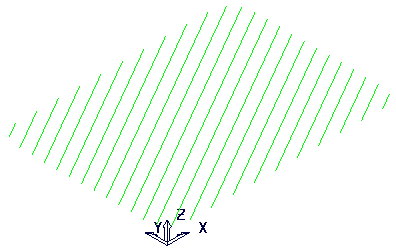

Angle —Enter the angle of the passes relative to the X axis.

- With an Angle of 0

:

:

- With an Angle of 30

:

:

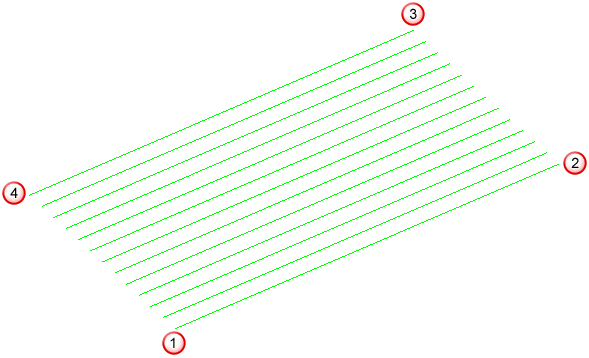

Start corner —Select the corner where machining starts. You can choose between four different start corners.

The toolpath starts from the lower-left corner of the boundary or the block when looking down the normal to the Face plane.

The toolpath starts from the lower-left corner of the boundary or the block when looking down the normal to the Face plane.

The toolpaths starts from the lower-right corner of the boundary or the block when looking down the normal to the Face plane.

The toolpaths starts from the lower-right corner of the boundary or the block when looking down the normal to the Face plane.

The toolpaths starts from the upper-right corner of the boundary or the block when looking down the normal to the Face plane.

The toolpaths starts from the upper-right corner of the boundary or the block when looking down the normal to the Face plane.

The toolpaths starts from the upper-left corner of the boundary or the block when looking down the normal to the Face plane.

The toolpaths starts from the upper-left corner of the boundary or the block when looking down the normal to the Face plane.

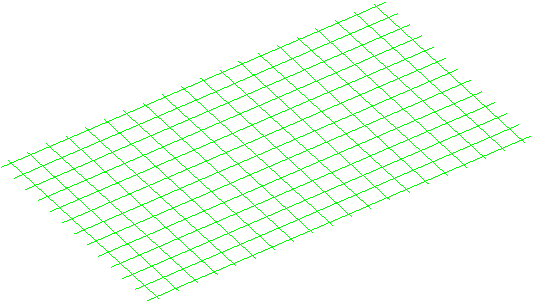

Perpendicular pass —Select to define a second raster pass perpendicular to the first one.

Shallow angle — Enter an angle to specify that the raster pass machines only the areas of the model that are steeper than this angle.

Optimize parallel pass — If a raster toolpath is created with a parallel and perpendicular pass, and with a shallow angle greater than 0 , select this option to trim the parallel pass so it does not machine the areas that the perpendicular pass machines.

, select this option to trim the parallel pass so it does not machine the areas that the perpendicular pass machines.

See examples of Perpendicular pass options.

Orderingdetermines how successive toolpath segments are machined.

Style —Select the order in which PartMaker machines the segments.

Tolerance — Enter a value to determine how accurately the toolpath follows the contours of the model.

Thickness — Enter the amount of material to be left on the stock within tolerance. Thickness is applied as an offset to the tool in all directions:

Stepover — Enter the distance between successive machining passes.