Use the High speed page to control various smoothing options to avoid sharp changes in tool direction when high speed machining.

For more information on the effects of smoothing, see Tool loading.

Profile smoothing — All Vortex toolpaths use arc fitting of profiles to avoid sharp changes of direction in internal corners.

Radius (tool diameter units) — Enter the radius as a proportion of the tool diameter. The value you enter determines when PartMaker inserts arcs.

The default value is 0.05. So, if you have a tool of diameter 20 mm (radius 10 mm) then the arc radius is 1 mm.

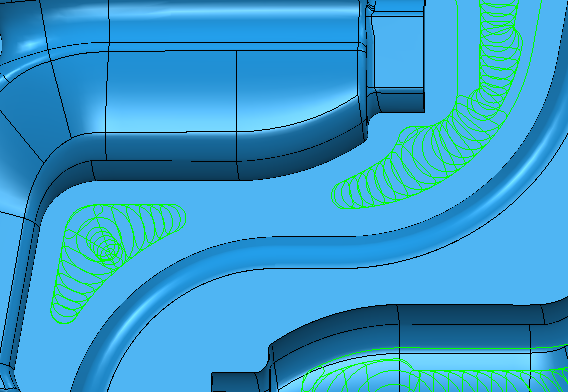

Using a Radius of 0.2 produces:

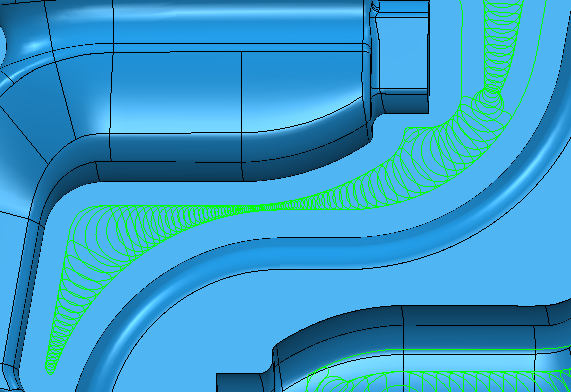

Using a Radius of 0.05 produces:

You can see that a small Radius value produces more trochoids.

Note: Small trochoids are inadvisable, if possible keep the trochoids larger than 1 mm.