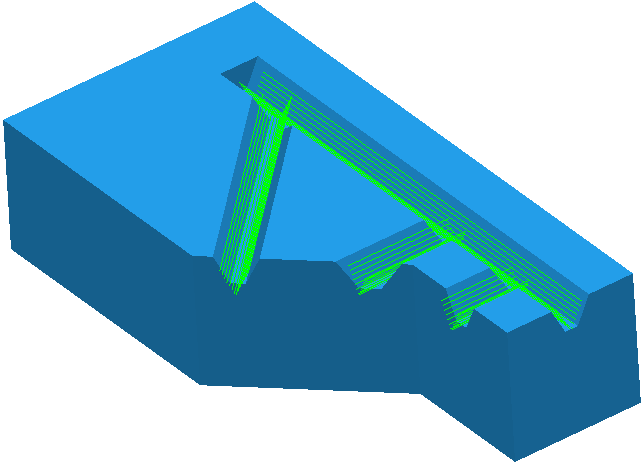

Use the Rib Machining strategy to machine channels in a mold which form ribs in the resulting injection-molded part. Typically, the channels are long, thin, and non-planar.

Rib machining requires:

- a pattern that is an approximate centreline of the channel.

- surfaces defining the walls and the base of the channel.

- a tool that fits inside the channel. The width of the channel must be between one and four times the diameter of the tool.

Rib machining frequently uses a form tool that reflects the exact shape of the channel.

The pages associated with the Rib Machining strategy are:

- Rib machining — The main page used to define a rib machining toolpath.

- High speed — Settings to create arcs in internal corners to eliminate sudden changes in tool direction which is essential for high speed machining.

- Automatic verification — Settings to automatically verify the toolpath when calculating it.

The remaining pages are common toolpath strategy pages.