Use the High speed page to control various smoothing options to avoid sharp changes in tool direction when high speed machining.

For more information on the effects of smoothing, see Tool loading.

Profile smoothing — Select to allow the arc fitting of profiles to avoid sharp changes of direction in internal corners.

If you select the Profile smoothing option, the Radius (tool diameter units) field becomes available. The radius is defined as a proportion of the tool diameter. The default value is 0.05. So, if you have a tool of diameter 10 mm (radius 5 mm) then the arc radius will be 0.5 mm.

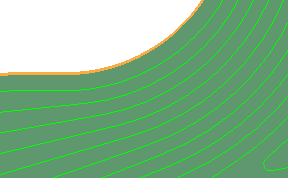

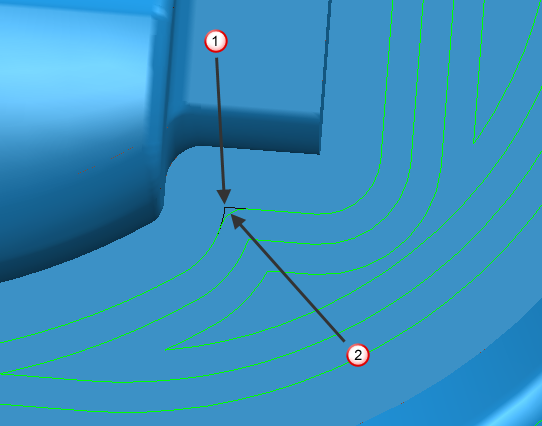

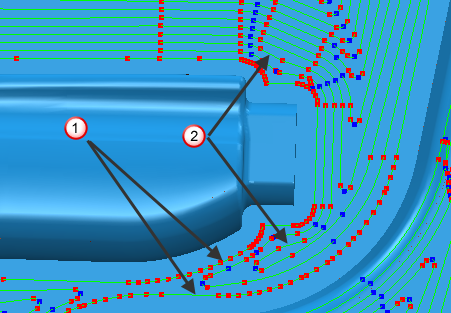

With a Radius of 0.2:

— Normal

— Normal

— Profile smoothed

— Profile smoothed

The light slice shows the Smoothed profile and the dark slice shows the Normal toolpath.

Arc fitting is of particular importance when high speed machining, as it eliminates sudden changes in tool direction. This works in a similar way to Arc fit corners for Constant Z finishing.

Raceline smoothing —Select this option to replace the standard offset with a smoother one that can achieve higher feed rates. When selected:

- Rounded corners replace sharp corners.

- The stepover changes from a fixed to a variable distance. The percentage defines the maximum deviation from the specified stepover. The maximum percentage is 40% of stepover. So, if you have a 10 mm stepover the maximum deviation from the original to the smoothed offset is 4 mm.

- Curvature continuity (not just tangency continuity) is maintained to prevent abrupt changes in force on a machine tool caused by sharp turns in a toolpath.

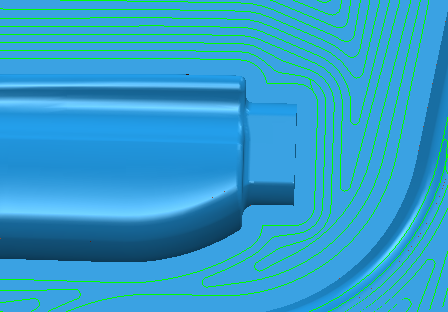

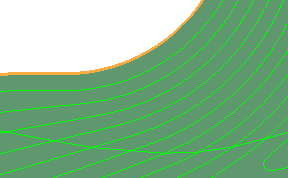

Raceline smoothing — Selected:

All passes, except for the profile pass are smoothed. There is a variable stepover.

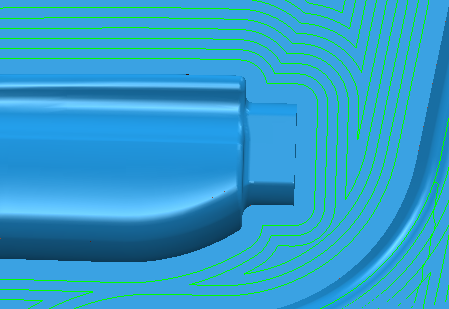

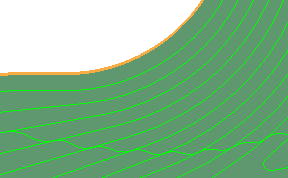

Raceline smoothing — Deselected:

All corners are sharp. There is a constant stepover.

Using the Raceline smoothing option produces a toolpath with fewer small arcs, which makes the toolpath more suitable for high-speed machining. The original profile has the same number of points in it - it is just the offset passes that have a reduction in the number of points.

— Profiling pass with the original number of points.

— Profiling pass with the original number of points.

— Offset passes with reduced numbers of points.

— Offset passes with reduced numbers of points.

Links — Select an option to specify whether PartMaker creates link moves between offsets within the toolpath.

- Straight:

- Smooth:

- None: